Technical Challenges of Tandem Press Brake Machines

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

the Core Capabilities Required of the Manufacturer to Make Tandem Press Brake Machine

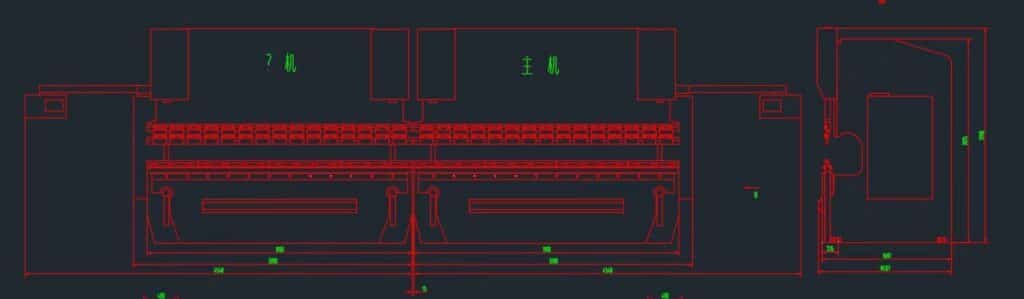

Tandem Press Brake Machine | Technical Guide for Long & Heavy Sheet Metal Bending

A tandem press brake machine is not simply two press brakes placed side by side.

In essence, it is a fully synchronized forming system that integrates two independent high-precision machines into one coordinated production unit.

Because of this, the technical complexity and the requirements placed on the press brake machine manufacturer are significantly higher than those for a standard single press brake.

The following sections explain the key engineering challenges and the real technical capabilities required to overcome them.

1. Ultra-High-Precision Multi-Axis Synchronization Control

Where is the challenge?

The most critical challenge of a tandem press brake machine is achieving real-time, absolute synchronization throughout the entire bending process, including:

-

Y1 / Y2 cylinders on both machines

-

Backgauge axes (X, R, Z, etc.)

-

Crowning / deflection compensation systems

-

Bending speed, speed-change points, and pressure build-up timing

Even a minor timing or position deviation can be geometrically amplified on long workpieces, resulting in:

-

Inconsistent bend angles

-

Part twisting

-

Abnormal tool loading or even tool damage

Manufacturer capability required

A qualified press brake machine manufacturer must possess:

-

Proven multi-machine CNC synchronization integration expertise

-

Deep understanding of tandem control logic in CNC systems (such as DELEM, ESA, or CYBELEC)

-

Practical experience compensating for hydraulic response delays and valve group differences

👉 This goes far beyond basic electrical integration—it requires long-term engineering know-how.

2. Extreme Structural Rigidity and Consistency Requirements

Where is the challenge?

In tandem operation:

-

A single extra-long workpiece spans two machines

-

Bending forces are distributed across both frames

-

Any micro-deformation in one frame directly affects overall bending accuracy

If the two machines differ in:

-

Frame rigidity

-

Ram deflection behavior

-

Elastic recovery characteristics

Then true synchronization is impossible, even with a perfect control system.

Manufacturer capability required

The manufacturer must have:

-

System-level structural design capability, not simple single-machine duplication

-

Full control over:

-

Frame plate thickness

-

Welding deformation and residual stress

-

Heat treatment and stress-relief processes

-

-

Stable manufacturing processes that ensure high mechanical consistency between the two machines

👉 This is a major barrier for manufacturers without strong structural engineering foundations.

3. Coordinated Crowning and Deflection Compensation Systems

Where is the challenge?

On a single press brake, crowning compensates only for that machine’s deflection.

In a tandem press brake machine, crowning becomes a cross-machine coordination problem:

-

Compensation values must change synchronously

-

Compensation curves must match precisely

-

Load distribution is more complex on long parts

If crowning systems are not perfectly coordinated:

-

The center angle may be correct while the ends deviate

-

One side may be over-compensated while the other is under-compensated

Manufacturer capability required

The manufacturer must provide:

-

Mature hydraulic or mechanical crowning coordination expertise

-

Integration of crowning logic into the overall synchronization control

-

Extensive real-world validation data from long-workpiece bending applications

👉 Without practical application data, stable results are extremely difficult to achieve.

4. System-Level Commissioning and On-Site Delivery Capability

Where is the challenge?

A tandem press brake machine is not a plug-and-play product. Final performance depends on:

-

Transportation conditions

-

Foundation flatness

-

Installation accuracy

-

Actual workpiece dimensions and materials

Commissioning is a true system-engineering process.

Manufacturer capability required

A competent press brake machine manufacturer must have:

-

Experienced commissioning engineers

-

Standardized procedures for:

-

Synchronization calibration

-

Long-part trial bending

-

Fine adjustment of crowning curves

-

-

Repeatable commissioning methods—not reliance on individual technician intuition

👉 This is one of the main reasons many manufacturers avoid tandem press brake projects.

5. Long-Term Stability and Reliability Engineering

Where is the challenge?

Tandem press brake machines must remain synchronized over time:

-

Hydraulic components age

-

Seals wear

-

Mechanical structures undergo micro-changes

Without stability-oriented design:

-

Synchronization accuracy degrades

-

Maintenance costs increase rapidly

Manufacturer capability required

The manufacturer must demonstrate:

-

Long-term operational validation

-

Redundancy and fault-tolerant design in hydraulic and control systems

-

Solutions to maintain synchronization accuracy over the machine’s lifecycle

6. Conclusion: What Does a Tandem Press Brake Machine Truly Test?

The challenge of a tandem press brake machine lies not in the number of machines, but in the ability to:

Reliably integrate two high-tonnage forming machines into a single, high-precision bending system.

It fundamentally tests a press brake machine manufacturer’s:

-

Structural engineering capability

-

Deep CNC and hydraulic integration expertise

-

Process understanding and real-world experience

-

Commissioning and delivery systems

-

Long-term reliability engineering

👉 This is why only a limited number of technically advanced press brake machine manufacturers can consistently deliver stable, high-performance tandem press brake solutions.

7. Proven Tandem Press Brake Experience from the MECA Engineering Team

Beyond theoretical design capability, practical manufacturing and commissioning experience is the decisive factor in successful tandem press brake projects.

The MECA engineering team has accumulated extensive real-world experience in tandem press brake machine manufacturing, system integration, and on-site commissioning. Our tandem solutions are not experimental concepts—they are validated production systems already in operation at customer facilities.

Verified Customer Applications

To date, more than 10 end users have successfully adopted MECA’s tandem press brake solutions across a range of tonnage and working lengths, including:

-

110T / 3100 mm

-

170T / 3100 mm

-

220T / 3100 mm

-

110T / 4100 mm

-

170T / 4100 mm

-

220T / 4100 mm

These configurations cover both:

-

Medium-length tandem applications for precision components

-

Long-bed tandem systems designed for large panels, cabinets, and structural sheet metal parts

FAQ

Q1: When does a tandem press brake machine become a better choice than a single long-bed press brake?

A tandem press brake machine is typically preferred when required bending length exceeds practical limits of a single-frame machine, or when transportation, installation, or workshop constraints make ultra-long single press brakes impractical.

It also offers flexibility: the two machines can operate independently for smaller parts when tandem operation is not required.

Q2: Are tandem press brake machines mainly used for higher tonnage, or longer parts?

Primarily for longer parts, not simply higher tonnage.

While tonnage is distributed across two machines, the real advantage lies in maintaining angle consistency and straightness over long workpieces such as panels, enclosures, or structural components.

Q3: Does tandem operation affect production efficiency compared to a single machine?

In most applications, tandem press brakes are used for low-to-medium batch, large-format parts, where setup accuracy is more critical than cycle speed.

However, when properly configured, tandem systems can still achieve stable and repeatable throughput without sacrificing precision.

Q4: How sensitive are tandem press brake machines to installation conditions?

More sensitive than standard machines.

Floor flatness, foundation rigidity, and alignment accuracy directly affect long-part bending results. This is why experienced manufacturers emphasize on-site calibration and system-level commissioning rather than relying solely on factory settings.

Q5: What questions should an end user ask a press brake machine manufacturer before choosing a tandem solution?

Instead of asking only about machine specifications, end users should ask:

-

What tandem projects have you already delivered?

-

How do you validate synchronization accuracy on long parts?

-

How is crowning coordinated between machines over time?

-

What commissioning steps are performed on-site?