Press Brake Machine Manufacturer Advice: Why Column Distance Matters in a Hydraulic Press Brake Machine (and Why It Affects Price)

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

When buyers compare a hydraulic press brake machine, they often focus on tonnage and working length first. Those are important—but they don’t tell the whole story. One parameter that quietly determines real-world usability, process flexibility, and long-term accuracy is column distance.

From a press brake machine manufacturer perspective, side frame distance is not just a “dimension on a spec sheet.” It defines usable working space inside the machine, influences structural design decisions, and affects how stable the press brake machine performs under load—especially for long parts and deep box parts.

This is also why side frame distance can have a direct impact on manufacturing cost and final quotation.

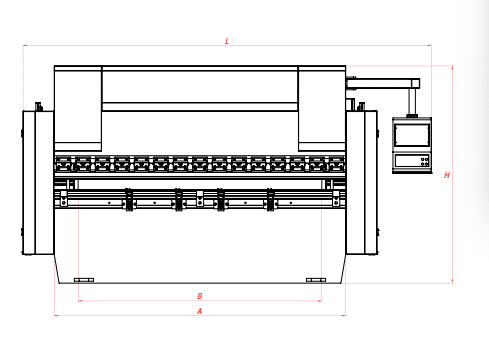

A: Bending Length

B: Columns Distance

Key Takeaways (Hydraulic Press Brake Focus)

- Column distance defines usable bending space, not just maximum sheet width. It affects clearance, part rotation, and multi-step bending feasibility.

- Long parts and deep box parts are the two most sensitive categories. Both require sufficient internal space, but they stress the machine in different ways.

- A larger column distance expands capability, but it must be matched with frame rigidity and deflection compensation to maintain accuracy.

- Different manufacturers list different column distance because of different design priorities (compact footprint vs broader process coverage).

- Column distance impacts cost and price because it changes frame size, machining difficulty, assembly alignment requirements, and compensation system needs.

What Is Column Distance in a Hydraulic Press Brake Machine?

Side frame distance refers to the clear span between the inner faces of the left and right side frames of a press brake machine. In practical terms, it helps define:

- how wide a workpiece can pass through the machine

- how much clearance is available for flanges during return stroke

- whether certain bending sequences are physically possible without collisions

- how tooling, backgauge, and safety systems can be arranged inside the working zone

Manufacturers measure column distance using calibrated tools and define it as a “clear” internal dimension. For buyers, it should be verified on the final machine drawing, not only in a brochure.

Simple buyer rule: side frame distance answers “Can my part actually move and bend inside this machine without interference?”

Why Column Distance Matters Beyond “Maximum Width”

(1) Usable Work Space for Complex Motion

During bending, parts do not stay flat. Flanges rise, boxes rotate, and multi-step sequences require clearance. Even if a sheet “fits” by width, it may still collide with side frames during later bends.

Column distance affects:

- deep flange clearance

- box turning space

- multi-step bending feasibility

- collision risk (machine + tooling + workpiece)

(2) Tooling and Backgauge Feasibility

Tooling height, die width, and the backgauge structure influence how much effective working space remains. If side frame distance is tight, certain tooling combinations become difficult, and backgauge travel can be restricted.

(3) Structural and Accuracy Implications (Hydraulic-Specific)

A hydraulic press brake machine applies force through hydraulic cylinders. Under load, the bed and ram can deflect. Side frame distance is linked to structural span and layout, which affects:

- rigidity behavior under tonnage

- deflection tendency during long bends

- the need for crowning/deflection compensation

- long-term repeatability and stability

Space affects “can you do it.” Structure and compensation affect “can you do it accurately and repeatedly.”

Who Feels Column Distance the Most? Real Production Scenarios

In real workshops, side frame distance becomes critical mainly for two categories: long parts and deep box parts. Many factories do both.

| Long-Part Customers (Angle Consistency + Throughput Sensitive) | |||

| Customer | Work piece | Pain points | Why side column distance matters |

| Electrical Enclosures / Control Cabinets | Cabinet doors, side panels, mounting plates, long stiffeners | Angle variation along length, end-to-end inconsistency, frequent re-setup | Supports stable handling of wide/long sheets and enables smoother multi-bend flow |

| Elevator Doors / Door Frames / Guard Panels | Long door edges, frame profiles, stiffeners | Frequent flipping/repositioning, scratches, slow alignment | Reduces repositioning and handling risks |

| HVAC Ducting and HVAC Enclosures | Long flanges, reinforcement bends, long edges | Sealing fit and assembly depend on consistent bends | Fewer errors, faster cycles, reduced rework |

| Architectural Cladding / Aluminum Panels | Large aluminum sheets with long fold edges | Surface damage, handling difficulty | More clearance reduces contact/scratch risk and improves workflow safety |

| Racking / Shelving / Long Structural Sheet Components | Beams, uprights, long edge stiffeners | high volume + tight cycle time | Stable setups and predictable throughput |

| Deep Box / Multi-Step Customers (Clearance + Collision Risk Sensitive) | |||

| Customer | Work piece | Pain points | Why column distance matters |

| Server Cabinets / Network Enclosures / Deep U-Parts | Deep boxes, U-channels, frames, internal flanges | Side collisions during return stroke, impossible bend sequences without special tooling | Why side frame distance matters: ensures enough clearance for turning and flange movement inside the machine |

| Appliance Shells (Ovens, Dishwasher Panels, Inner Liners) | Deep shells, multi-step bends, complex sequences | limited clearance forces process compromises and extra steps | Wider internal space supports more bend options with fewer workaround setups” |

| EV / Charging Equipment / Battery-Related Sheet Parts | Accuracy and consistency affect fit/sealing; complex sequences common | High assembly precision is required, as minor deviations can easily result in inadequate sealing. | Supports feasibility while demanding stable compensation and repeatability |

| Medical Equipment Covers / High-Finish Enclosures | Deep covers, cosmetic edges | Cosmetic damage and rework cost are high | Better clearance reduces collision/scratch risk and scrap |

| Job Shops (High Mix, Low Volume) | “Everything”: long parts, deep boxes, irregular geometries | Machine limitations = lost orders

|

Broader process envelope increases quoting capacity and reduces job rejection |

Why does the column distance vary so much among different manufacturers?

Buyers often notice significant parameter differences among various press brake machine manufacturers. This is largely due to different design philosophies and engineering priorities, rather than a simple matter of “right or wrong.”

| Design approach A

Compact side-frame inner distance |

Design approach B

More generous processing space |

| Emphasizes a compact machine footprint and reduced floor space | Better suited for wide and box-type parts, with greater process flexibility |

| Optimized for standard narrow parts and routine bending operations | Facilitates complex bending sequences and reduces part repositioning |

| Offers limited clearance for deep boxes, long flanges, and complex bending sequences | Requires higher frame rigidity, alignment accuracy, and compensation performance |

| Conclusion: To a certain extent, the side-frame inner distance reflects whether a machine is designed for standard operating conditions or for broader process coverage. | |

Performance Differences Buyers Actually See

(1) Part Feasibility and Process Coverage

- Smaller distance: some parts require extra repositioning, segmented bending, or process changes

- Larger distance: more parts can be completed in fewer steps, with fewer compromises

(2) Efficiency and Handling Stability

If clearance is tight, operators spend more time on:

- part rotation and re-alignment

- avoiding collisions

- repeated setups

Adequate space reduces these friction costs.

(3) Long-Bend Accuracy and Consistency (Structure + Compensation)

For long parts, accuracy depends on the complete system:

- frame/ram/bed rigidity

- hydraulic stability under load

- crowning (manual or CNC)

calibration and alignment quality

A press brake machine with sufficient internal space and proper rigidity/compensation will deliver more stable long-bend results over time.

Why Column distance Can Affect Cost and Quotation

After understanding the functional value, it becomes easier to see why side frame distance may affect pricing.

In many hydraulic press brake machine designs, increasing side frame distance is not a simple dimension change. It often drives a chain of requirements, such as:

- larger/heavier frame components to maintain rigidity

- longer machining and higher alignment requirements

- stronger crowning/compensation needs for long bends

- additional assembly and calibration work to ensure accuracy and repeatability

That’s why two machines with similar tonnage and working length may have different manufacturing cost levels when side frame distance (and the structural/compensation system behind it) differs.

Buyer takeaway: a higher quotation linked to side frame distance often reflects a larger process envelope and the structural work required to keep performance stable.

Buyer Checklist: What to Ask a Press Brake Machine Manufacturer

To compare quotations fairly, ask for clarity on these points:

- What is the column distance—is it true internal clear distance?

- For my long parts and deep box parts, can you confirm clearance and collision riskwith drawings or simulation?

- What crowning/deflection compensation is included (manual or CNC)?

- What rigidity measures are used (frame structure, machining method, stress relief/aging)?

- What backgauge axes and travel are provided for my typical part family?

- How is accuracy verified for long bends (multi-point angle check, repeatability under load)?

Conclusion

Side frame distance is one of the most practical parameters for evaluating a hydraulic press brake machine because it connects directly to real production: part feasibility, workflow efficiency, collision risk, and long-term accuracy. Different manufacturers choose different values based on design priorities, and those choices influence both performance and cost.

If your work includes both long parts and deep box parts, side frame distance becomes even more important—because it expands what you can make today and reduces process limitations tomorrow, while requiring the structural and compensation design needed to keep bending results stable.