6 Aixs

Cost-Effective Hydraulic Press Brake Machine

Check the PriceHighlights of M-series CNC Hydraulic Press Brake

Multiple Models

- The product models range from 60t/2050mm to 600t/6100mm

- Professional transportation solutions for large-tonnage machines

- Tandem press brake solution can be customized

- Flexible configurations to suit different budgets

Energy Efficiency

Equipped with a servo motor as standard.

-

Up to 40% Energy Savings, significantly reducing electricity and operating costs

-

±0.01 mm repeatability, ensuring consistent bending accuracy and less rework

-

Noise reduced by 30–40%, creating a quieter and safer workshop

-

Oil temperature reduced by 10–15°C, extending hydraulic component service life

-

Faster response and cycle time, improving productivity by up to 20%

Safety Guarantee

Standard Configuration

- Side safety guard doors

- LED light on Front and Back

- Emergency switch on foot pedal

Optional Configuration (CE certificate):

- Laser safety light curtain

- 5-point monitored hydraulic valve

- Remote-controlled roll-up rear door

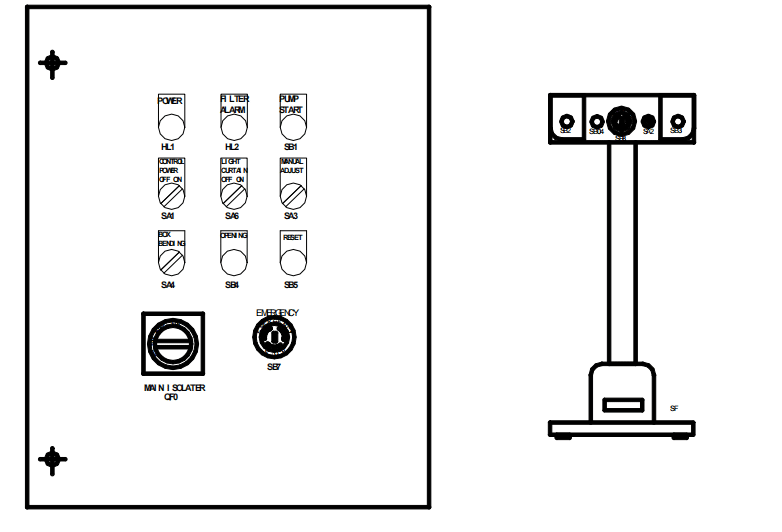

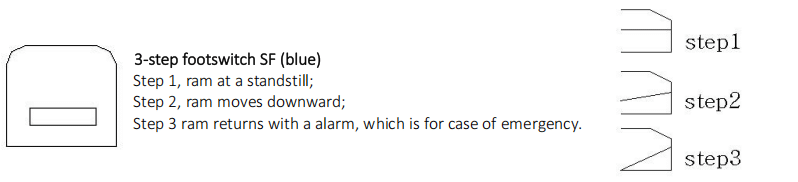

- Single 3-step foot switch

Sturdy & Deformation-resistant Frame

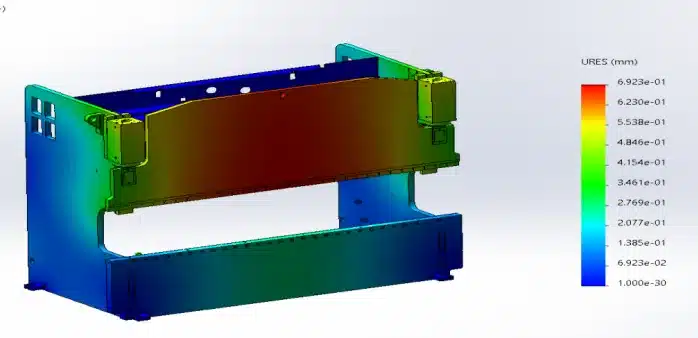

The CNC press brake frame and components are designed using advanced 3D modeling and finite element analysis (FEA) simulation.

The frame features an integrated steel plate welded structure, offering exceptional strength, excellent rigidity, and robust resistance to torsional deformation. To eliminate internal stress and ensure long-term precision stability, the entire frame undergoes shot blasting and other stress-relief treatments, enhancing the machine’s performance and longevity.

The steel plates used for the machine frame are thicker than those of similar products on the market, providing superior overall rigidity and significantly reducing deformation accumulation over long-term use. A robust frame offers a stable foundation for the synchronized movement of the ram, ensuring precise synchronization accuracy on both sides. During rapid descent or stamping operations, the thicker frame effectively absorbs vibrations, minimizing relative displacement between the workpiece and tooling, thus maintaining machining accuracy.

The left image shows the frame thickness of the 225t/4100mm press machine

The Potential Risks of Non-Compliant Processes in Press Brake Machine Manufact: Plate Cracking

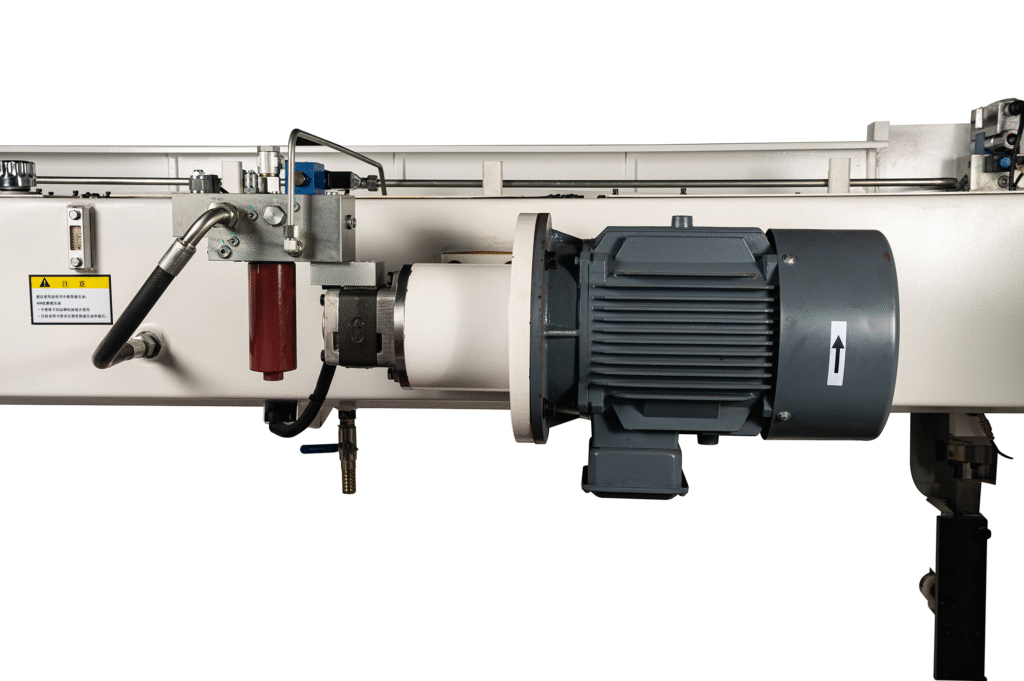

ESTUN Servo Motor

- Up to 40% Energy Savings, significantly reducing electricity and operating costs

Asynchronous Motors :

Run continuously, with fixed energy consumption (e.g., a 10kW motor’s standby power consumption accounts for 30%).

Servo Motors

Consume power only when operating, achieving over 40% energy savings. Save at least $1,000 annually ($0.17 per kWh*10h/per day).

- ±0.01 mm repeatability, ensuring consistent bending accuracy and less rework

- Noise reduced by 30–40%, creating a quieter and safer workshop

- Oil temperature reduced by 10–15°C, extending hydraulic component service life

- Faster response and cycle time, improving productivity by up to 20%

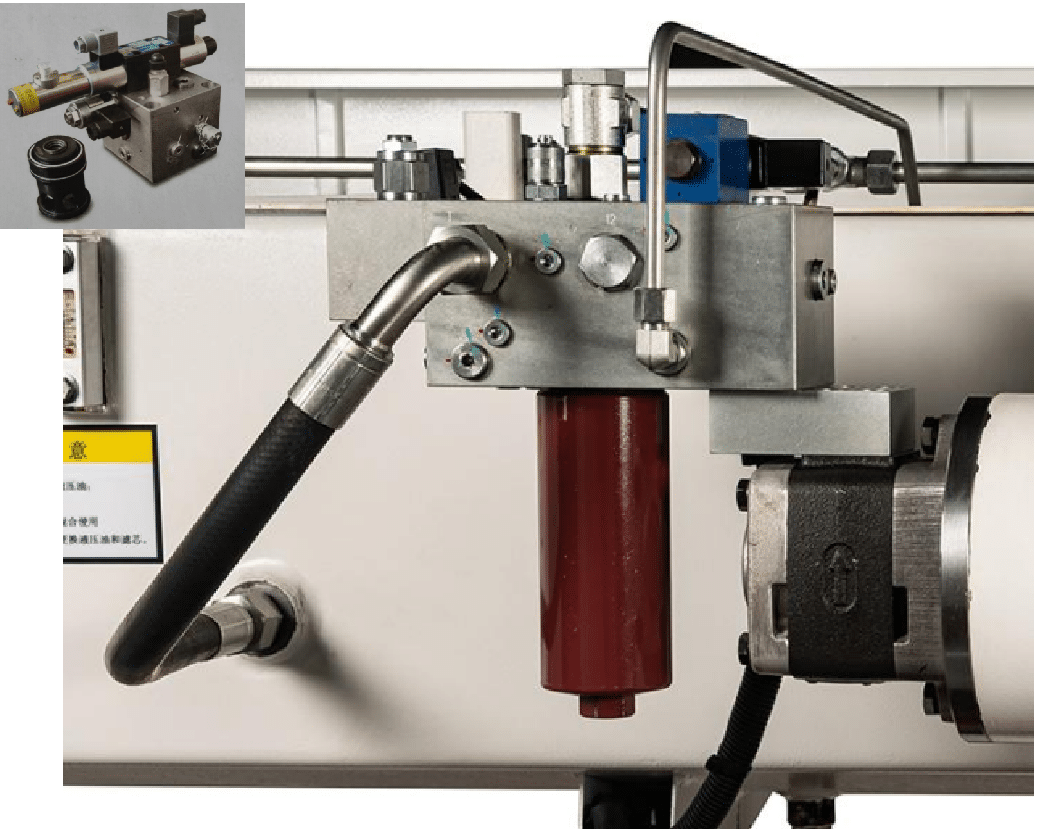

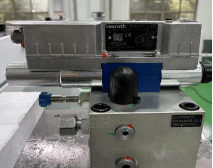

Rexroth/Hawe Pump

- The system adopts world-leading German Rexroth hydraulic control technology, achieving extremely high synchronization control accuracy.

- The oil pump uses Le high-pressure internal gear pumps, capable of withstanding high pressure and operating with low noise.

- The hydraulic system features overload relief protection, ensuring safety and reliability.

- The hydraulic system includes two-stage filtration, with high filtration precision.

- The high-pressure filter is equipped with a clogging indicator function.

- There is a clear and intuitive oil level height display.

- Modular technology is used, ensuring a compact structure, strong sealing performance, easy maintenance, and long service life.

- The hydraulic piping system consists of Parker-type ferrule fittings and seamless steel pipes, ensuring leak-free operation and cleanliness.

CE configuration use Hawe pump and hydraulic valve

"0" Leakage Cylinder

- Sturdy and Reliable: Crafted from premium forged materials (45# steel, fully forged) and subjected to rigorous heat treatment (annealing, normalizing, and quenching).

- Precision and Durability: Achieved with advanced machining technology (CNC gantry milling), critical surface enhancement techniques (rolling, honing, copper infusion, chrome plating, and polishing) to ensure high precision, hardness, excellent surface finish, and superior wear and corrosion resistance.

- Superior Sealing: Integrated flow channels minimize leak points, while the high precision and special treatment (copper infusion) of key mating surfaces (inner holes, guide surfaces) provide a strong foundation for optimal sealing.

- Contamination-Free: All parts are ultrasonically cleaned after machining to completely remove residue and metal filings, preventing “scoring” during assembly. High-pressure oil lines are thoroughly cleaned to avoid contamination, protecting hydraulic valves and cylinders and eliminating contamination-related failures from the outset.

- Quality Assurance: Non-destructive testing, precision machining, and stringent pressure retention tests ensure the final product meets the highest quality standards.

Schneider AC Contactor

- The main electrical components are from the Schneider brand, ensuring safety, reliability, long service life, and strong anti-interference capabilities. The control station is equipped with a movable footswitch, offering functions such as power on and emergency stop. The wiring of the electrical cabinet is reasonable and clear, making maintenance or troubleshooting easier, while also providing excellent heat dissipation.

- The electrical setup complies with CE certification requirements for optional configuration.

4 Axis/6 Axis Optional

- Drives of X- and R-axis: ESTUN Servo Motor

- 4+1 Axis:Y1、Y2、X、R、+V;

- 6+1 Axis:Y1、Y2、X、R、Z1、Z2、+V;

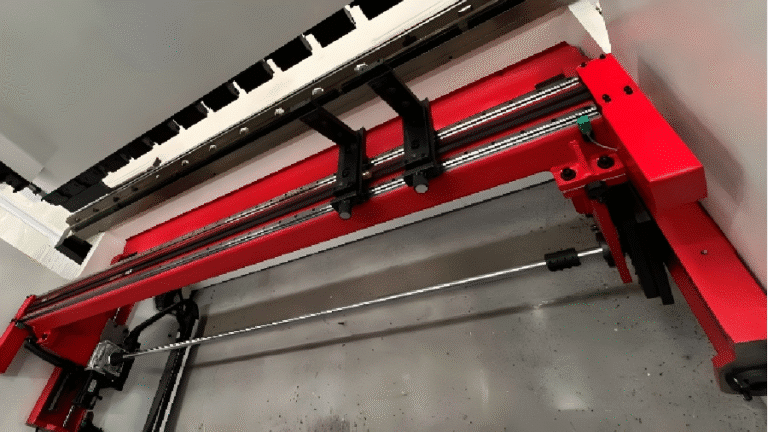

The Diameter of Guide Rail and Screw ≥20mm

- Enhanced positioning stability – thick backgauge rails keep the workpiece steady for precise bending.

-

Longer service life – robust rails resist wear and deformation, reducing maintenance and replacement costs.

-

Supports heavy and long workpieces – able to handle higher loads and long sheets efficiently.

-

Improved production efficiency – stable positioning minimizes rework and adjustment time.

CNC Controlled Crowning System

Working Principle

-

Precision wedge blocks with inclined surfaces installed beneath the worktable.

-

CNC system drives wedges via servo motors or high-precision electro-hydraulic proportional valves.

Dynamic Adjustment

-

Real-time, automatic compensation based on:

-

Required bending tonnage (CNC calculated)

-

Workpiece length, material, and thickness

-

Die type

-

Precision & Flexibility

-

Fully automatic, dynamically adaptive.

-

Compensation curve fine-tunes in real time to keep upper and lower dies perfectly parallel under load.

Lightweight Foldable Front Support

- The front supportercan slide along a linear guide rail, allowing the spacing to be adjusted according to the length of the workpiece.

- The supporter can be rotated and folded parallel to the press brake worktable, making it convenient for transportation and storage.

Equipped with Throat Compensator & Magnetic Scale

Throat Compensator

- Accurately measure the deformation and provide feedback compensation to ensure the bending accuracy.

- Effectively prevent non-standard workpieces from colliding with the interference detection unit

Italy GIVI Magnetic Scale

-

±0.01 mm high precision – ensures consistent, accurate bends and reduces scrap.

-

Reliable and durable – resistant to dust, oil, and vibration for long-term stable performance.

-

Real-time CNC feedback – enables fast, precise adjustment and improves production efficiency.

Multiple CNC Systems Available

4+1 Optional

- Cybtouch CT 12

- ESA 840

6+1 Optional

- DELEM DA-66T

- DELEM DA-69T

- ESA 840

CE/Non-CE Option

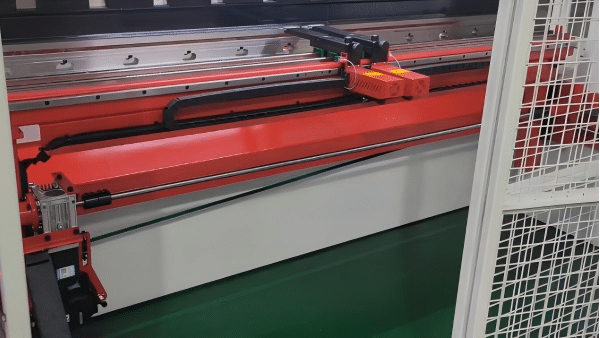

LED Light on Both Front & Back

Optional Configuration

Configuration Selection Guide of Hydraulic Press Brake

| Configuration | √Standard ❏Options | Configuration | √Standard ❏Options |

|---|---|---|---|

| Axis | √ 4+1 | Crowning System | √ Mechanical Compensation Motorized by CNC |

| ❏ 6+1 | Sealing Components | √ PARKER | |

| 4+1 CNC System | √ DELEM DA-53T | Foot Pedal | √ Double foot pedal (Non CE) |

| ❏ Cybelec CT 12 | ❏ Single 3-step foot switch comply with CE Step1,ramata stand still; Step2,rammoves downward; Step3,ram returns with a alarm, which is for case of emergency. |

||

| ❏ ESA 840 | |||

| 6+1 CNC System | ❏ DELEM DA-66T | ||

| ❏ DELEM DA-69T | LED Light | √ LED lights on both front and back | |

| ❏ Cybelec CT15 | Punch Clamp | √ High Quality Manual Clamp | |

| ❏ ESA 840 | ❏ Hydraulic Automatic Clamping Device | ||

| Servo Main Motor | √ ESTUN | Die Clamp | √2V-'T’Quick Change Bottom |

| Hydraulic System | √ REXROTH (Germany ) | Toolings | √Promecam Punch 85° |

| ❏HAWE 5-Point Monitoring Safety Pressure Valve (CE) | √ 2V Die | ||

| Hydraulic Cylinder | √ Zero leakage Hydraulic Cylinder | ❏4V 60mm Die | |

| Magnetic Scale | √ Italy GIVI | ❏Customized Toolings | |

| Linear Guide Rail | √ Diameter not less than 20mm | Back Protector | √ Barrier |

| Ball Screw | √ Diameter not less than 20mm | ❏ Electric Auto Alu Roll-up Door | |

| Oil Pump | √ Le (Brands under REXROTH ) | Safety Light Curtain | ❏DSP-AP+MCS |

| Servo Motor (back gauge) | √ ESTUN | ❏AKAS lc2m+FMSC | |

| High-Pressure Pipeline | √ PARKER | ❏AKAS lc2m+GMSA (Contain speed monitoring) | |

| AC Contactor | √ Schneider | CE | ❏Electrical Setup & CE certificate |

CNC Press Brake Machine for Sale

»Check Technique Parameter

| Technical Specifications/Model) | M1 60/1500 | M3 110/3100 | M3 170/3100 | M3 220/3100 | M4 110/4100 | M4 170/4100 | M4 220/4100 | M4 320/4100 |

|

|---|---|---|---|---|---|---|---|---|---|

| Nominal Force (KN) | 600 | 1100 | 1700 | 2200 | 1100 | 170 | 2200 | 3200 | |

| Bending Length (mm) | 1500 | 3100 | 3100 | 3100 | 4100 | 4100 | 4100 | 4100 | |

| Side Frame Distance (mm) | 1200 | 2600 | 2600 | 2600 | 3600 | 3600 | 3600 | 3600 | |

| Ram Stroke (mm) | 215 | 200 | 200 | 200 | 200 | 200 | 200 | 300 | |

| Opening Height(mm) | 525 | 575 | 575 | 575 | 575 | 575 | 575 | 680 | |

| Oil volume (L) | 75 | 180 | 180 | 180 | 350 | 350 | 350 | 350 | |

| Throat depth (mm) | 350 | 410 | 410 | 410 | 410 | 410 | 410 | 410 | |

| Ram Speed | Down Speed (mm/s) | 200 | 220 | 180 | 160 | 220 | 180 | 160 | 120 |

| Pressing (mm/s) | 18 | 14(10) | 11 | 9 | 14 | 11 | 9 | 8 | |

| Return Speed (mm/s) | 200 | 150 | 140 | 120 | 150 | 120 | 110 | 100 | |

| Electrical Parameters | Main Motor Power( KW) | 8.7 | 10.8 | 13.2 | 16.7 | 13.2 | 13.2 | 16.7 | 21.3 |

| Working voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | |

| Backgauge Data Sheet Reference | Axis travel(mm) | 500 | 620 | 620 | 620 | 620 | 620 | 620 | 620 |

| X Axis working speed(mm/s) | 400 | 250 | 250 | ±0.10 | 250 | 250 | ±0.10 | 250 | |

| X Axis Accuracy(mm) | ±0.05 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | |

| R Axis travel(mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| R Axis working speed(mm/s) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| R Axis Accuracy(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| Z Axis travel(mm) | 350 | 1900 | 1900 | 1900 | 2000 | 2000 | 2900 | 2900 | |

| Z Axis working speed(mm/s) | 1200 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | |

| Z Axis Accuracy(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| Y Axis Accuracy(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Y Axis Repeat Accuracy(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Workpiece straightness(mm) | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | |

| Bending angle accuracy (°) | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | |

| Dimension | Length mm | 2300 | 3950 | 3970 | 3970 | 4970 | 4970 | 4970 | 4970 |

| Width mm | 1400 | 1450 | 1550 | 1750 | 1850 | 1550 | 1750 | 1850 | |

| Height mm | 2550 | 2695 | 2695 | 2695 | 2765 | 2695 | 2695 | 2890 | |

| Weight (KG) | ~5000 | ~6900 | ~8200 | ~11800 | ~8200 | ~10400 | ~14800 | ~16000 | |

Large Press Brake

Tandem Hydraulic Press Brake

→110t/3100mm*2 Tandem

→170t/3100mm*2 Tandem

→220t/3100mm*2 Tandem

→170t/4100mm*2 Tandem

→220t/4100mm*2 Tandem

→320t/4100mm*2 Tandem

Request a Technical Proposal Now!

FAQ

What models are available for your press brake products?

“We offer three main product series: M, H, and E. The M-series has the most comprehensive range, including 60t/2050mm, 60t/2550mm, 110t/3100mm, 110t/4100mm, 170t/3100mm, 170t/4100mm, 220t/3100mm, 220t/4100mm, 250t/4100mm, 320t/3100mm, 320t/4100mm, 400t/4100mm, and 500t/4100mm. The H-series, on the other hand, includes 60t/1500mm, 60t/2050mm, 60t/2550mm, 110t/3100mm, 170t/3100mm, 220t/3100mm, 110t/4100mm, 170t/4100mm, and 220t/4100mm, offering a smaller selection than the M-series. This is because larger press brakes require a closed-frame cover, which significantly increases the costs and complexity of installation, transportation, and maintenance.

Can you provide tandem press brake?

Yes, we can. 170t/3100mm and 220t/3100mm are the tandem press brake we make most often. We have extensive experience in tandem solution. You can contact our sales consultants to request a video.

Can I customize my own brand?

The H-series design can be customized with your choice of colors and logo. After cooperation, we will provide product renderings and videos featuring your brand’s colors and logo, aligning with your marketing strategy. If the H-series design doesn’t meet your needs and you require a completely new press brake design, we can arrange for an industrial designer to create a tailored solution for you.

What is your delivery lead time?

The lead time for standard models is 45-50 days, and for custom products, it is 60-70 days.

I need CE certification. Can you provide it?

Yes. We can make electrical safety settings for the system according to CE requirements and provide the CE certificate.

I am an end user, and I’m not sure how to choose the right press brake for my needs. Can you provide recommendations?

If you can describe the materials you bend regularly, including the material type, thickness, or provide a workpiece drawing, our engineers will assist you in selecting the right model.

Do you offer a warranty?

We promise one-year warranty. During this period, any quality issues with parts caused by factors other than human error can be repaired or replaced free of charge. However, you will need to cover the shipping costs both ways.

How do you provide after-sales service?

After both parties sign the sales contract, based on the specific requirements of the customer, free remote video guidance and training could be provided.The training content includes:

- Principles and introduction of the CNC press brake.

- System components of the CNC press brake.

- Operation of the CNC press brake.

- Maintenance of the CNC press brake.

- Solutions for common issue

If you need a on-site service, you shall provide round-trip airfare, accommodation, and a daily allowance of the engineer.

Where is the shipping address?

Our press brake machines are shipped from Yangzhou, China. If you already have other suppliers in China but wish to purchase our bending accessories, we can ship them for free to your existing shipping address in China.

The shipping cost is too high. How can I reduce it?

Typically, a 40ft HC container can fit 2 press brakes with a 4100mm or smaller working length. We recommend purchasing 2 units at once to share the shipping cost.

How are large press brakes transported?

Press brakes over 320t in tonnage need to be disassembled before shipping and then reassembled at your factory. We have specialized shipping solutions in place. Generally, our after-sales team will be required to install the machine on-site, with at least 2 engineers. The installation process typically takes about one month, and these costs will be included in the quotation provided to you.