Understanding the Functionality of Axes in a Press Brake Machine

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

(3 Axis CNC Press Brake | 4 Axis CNC Press Brake | 6 Axis CNC Press Brake)

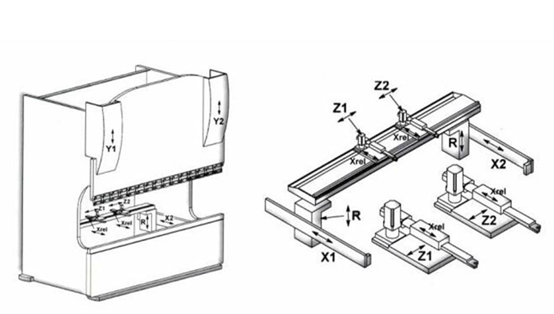

Press brake specifications such as 3 axis cnc press brake, 4 axis cnc press brake, and 6 axis cnc press brake often refer to the machine’s controlled movement axes (X, Y, R, Z, V). Understanding these axes is essential for selecting the right CNC press brake and achieving precise bending performance.

What is the Function of the Axes in a Press Brake Machine?

The axes in a press brake refer to the controlled movement paths within the machine that can be precisely adjusted during the bending process. These axes control the movement of the ram, backgauge, and other components, allowing accurate positioning of the metal sheet and achieving precise bending angles. Each axis plays a vital role in the performance and versatility of a press brake.

Whether you’re using a 3 axis cnc press brake, 4 axis cnc press brake, or a 6 axis cnc press brake, the core concept remains the same—the more axes you have, the more flexibility and automation the machine provides.

Modern CNC press brakes use a combination of multiple axes to manage tasks such as positioning the workpiece, aligning backgauge fingers, and compensating for machine deflection.

Key Axes in a CNC Press Brake Machine

In CNC-controlled press brake machines, these axes are managed by a computer control system, enabling automatic adjustments for enhanced precision.

-

-

Y-Axis: Controls the vertical movement of the ram and bending depth.

-

X-Axis: Positions the backgauge forward and backward.

-

R-Axis: Adjusts the height of the backgauge fingers.

-

Z-Axis: Controls lateral movement of the backgauge fingers.

-

V-Axis: Used for crowning compensation to counter machine deflection.

-

Y-Axis (Y1 & Y2) — Vertical Ram Movement

The Y-axis controls the upper beam’s vertical movement. In CNC machines, Y1 and Y2 operate independently to ensure synchronized motion and consistent bending accuracy.

This axis is essential in every CNC model, whether it’s a 3 axis, 4 axis, or 6 axis cnc press brake.

X-Axis (X1 & X2) — Backgauge Front/Rear Positioning

The X-axis determines the horizontal positioning of the backgauge, which controls flange length.

-

Critical for repeat accuracy

-

Allows precise positioning for consistent bends

-

Appears in 3 axis cnc press brake and higher

R-Axis (R1 & R2) — Vertical Backgauge Movement

The R-axis controls how the backgauge fingers move vertically.

Useful for:

-

Custom-shaped parts

-

Workpieces with height differences

-

Multi-step bending operations

Included in 4 axis cnc press brake and above.

Z-Axis (Z1 & Z2) — Backgauge Lateral Positioning

The Z-axis allows the backgauge fingers to move left and right independently.

Benefits:

-

Faster setup for small or multi-bend parts

-

Ideal for asymmetrical workpieces

A key feature of a 6 axis cnc press brake.

V-Axis — CNC Crowning Compensation

The V-axis automatically compensates for deflection during bending.

Essential for:

-

Long workpieces

-

Thick materials

-

Maintaining precise angles

Standard on all Meca CNC press brakes.

Understanding CNC Press Brake Axis Configurations

| 2 Axis | X, Y | Suitable for simple bending tasks. |

| 3+1 Axis | Y1, Y2, X, +V | A basic configuration for standard bending applications. |

| 4+1 Axis | Y1, Y2, X, R,+V | More versatile for varying flange heights. |

| 6+1 Axis | Y1, Y2, X, R, Z1, Z2,+V | Highly flexible, ideal for complex and multi-bend parts. |

| 8+1 Axis | Y1, Y2, X1, X2, R1, R2, Z1, Z2,+V | Advanced bending performance for demanding manufacturing. |

All Meca press brakes come standard with CNC-controlled crowning (V-axis).

You can choose 4+1 axis or 6+1 axis CNC press brake, and configurations can be fully customized.