What Influences Press Brake Machine Performance Most?

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

What Influences Press Brake Machine Performance Most?

You get the best results with a press brake machine when it is well-designed and built strong. Studies show that many things can change how well it works. The table below shows what is most important:

| Factor Type | Description |

|---|---|

| Sheet Material | Changes how well the workpiece bends. |

| Press Brake Tooling | Changes how exact the bending process is. |

| Machinery | Changes how accurate the bending is. |

| Human Factors | Changes bending accuracy based on operator skill. |

You can learn a lot by knowing about these things. This helps you if you have lots of experience or if you are new to metal forming.

Key Takeaways

- A strong frame is very important for press brake accuracy. It helps keep the machine steady. This makes sure the results stay the same each time.

- Doing regular maintenance on tools and machines stops mistakes. Clean your tools and look for damage every day. This helps keep the quality high.

- Operator training is very important. Skilled operators make fewer mistakes. They also work faster and better. This helps make better products.

- Material consistency is important for good bends. Always check the thickness and type of metal before you start.

- Advanced features like CNC controls and automation help with precision and speed. Use new technology to make your work better.

Press Brake Machine Design

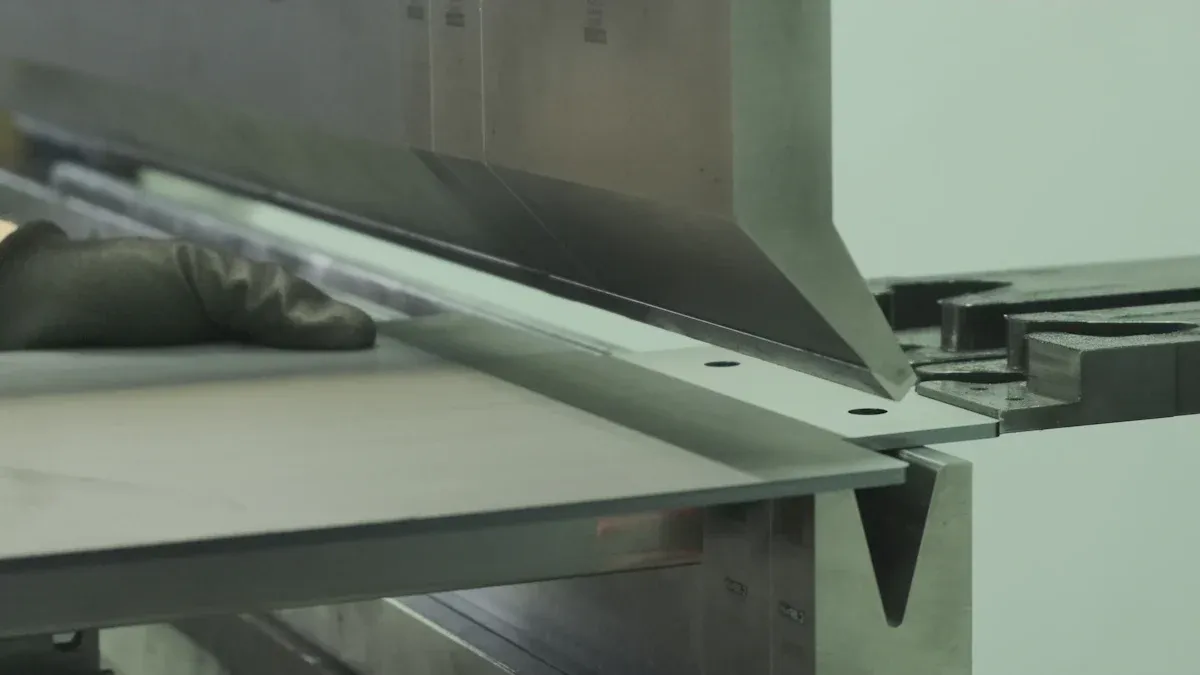

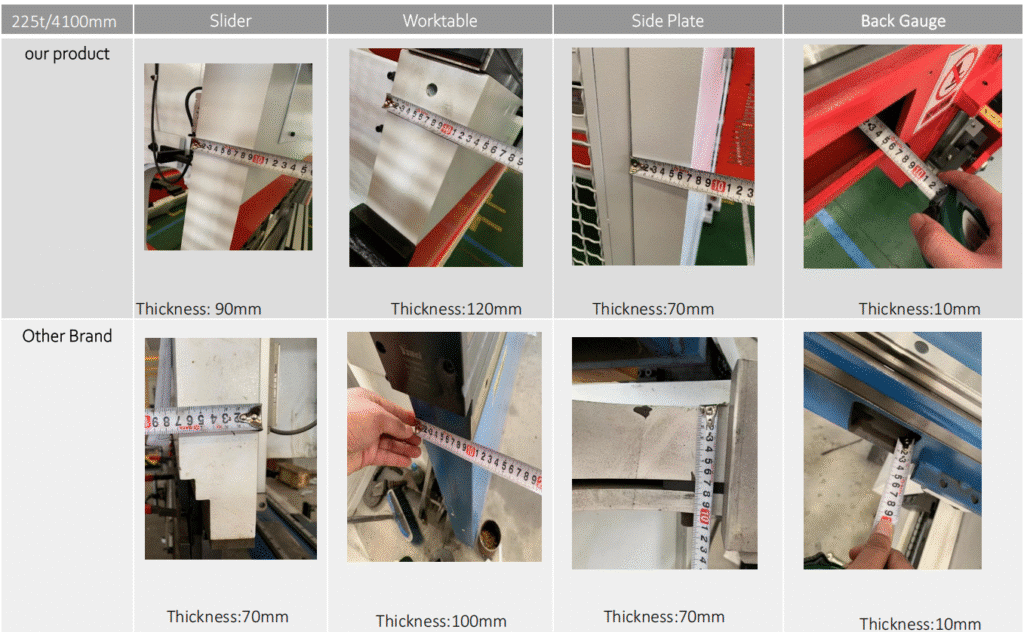

Frame Rigidity

A press brake machine needs a strong frame. The frame keeps the machine steady when it bends metal. If the frame is very sturdy, it can handle heavy pressure. This helps you get the same results every time. A tough frame also helps the machine last longer. It keeps your workpieces accurate. If the frame bends or twists, your parts will have mistakes. Big press brake machines use thick steel and strong designs. This helps them stay strong when working hard.

System Quality

The system inside the press brake is important too. You can pick hydraulic or electric systems. Each one is good for different jobs. The table below shows how they are different:

| Feature | Hydraulic Press Brake | Electric Press Brake |

|---|---|---|

| Bending Force | Strong force, good for thick metal | Less force, best for thin metal |

| Speed | Fast, can change pressure | Slower, can bend many parts automatically |

| Precision | Steady, controls bending angle well | Very exact with servo motors |

| Energy Efficiency | Uses more power, needs hydraulic oil | Saves power, only uses energy when moving |

| Maintenance Needs | Hard to fix, needs experts | Easy to fix, has fewer moving parts |

| Environmental Impact | Uses more oil, bigger impact | Less noise, smaller impact |

Pick the system that works best for your shop. Electric systems save energy and are easier to care for. Hydraulic systems are better for tough jobs and thick metal.

Advanced Features

New press brake machines have special features. These help you work faster and safer. CNC controls let you program hard bends. This lowers mistakes. Automation helps you make many parts that look the same. Safety systems protect you and your team. The table below shows some features and what they do:

| Feature | Benefit |

|---|---|

| Automation | Makes work easier and keeps results the same |

| Automatic backgauge systems | Changes jobs quickly and saves time |

| Multi-axis control | Helps with hard bends and better accuracy |

| Safety mechanisms | Keeps you safe and lowers accident risk |

| Real-time monitoring systems | Watches the process and helps get better results |

Extra safety comes from light curtains, interlock systems, and sensors. These stop the machine if something is wrong. Ergonomic designs make your workspace safer and more comfortable. Using new technology and strong frames helps you get better results and work faster.

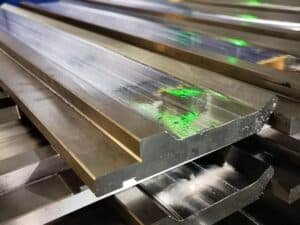

Tooling Quality

Tool Design

You need to choose the right tooling for your press brake machine to get accurate bends. The shape of the die opening and the punch radius changes the final bend angle and radius. If you use the wrong tool, you might see marks or cracks on your workpiece. Good tooling design spreads out the force and avoids sharp corners. This helps prevent cracks and makes your tools last longer. Some tools have features that help get rid of heat, which keeps them from wearing out too fast.

- The geometry of your tooling affects the bend angle and surface finish.

- Picking the right tool for each material type and thickness helps avoid problems.

- A strong design reduces stress and keeps your tools working longer.

Tool Condition

You should check your tools every day. Clean the punches and dies to remove any metal shavings, oil, or dirt. If you see cracks, chips, or signs of wear, replace the tool right away. Worn or damaged tools can cause mistakes in your bends and lower the quality of your parts. Regular maintenance keeps your press brake machine running smoothly and helps you avoid downtime.

- Clean tools daily to stop wear.

- Inspect for damage and replace tools as needed.

- Maintenance extends tool life and keeps your work accurate.

Tip: Well-maintained tools save you money and time by reducing errors and machine stops.

Alignment

Proper alignment of your tooling is key for consistent results. If your tools are not lined up, you might get uneven pressure during bending. This can cause the angles and sizes of your bends to be off. When you make sure your tools are aligned, you get the same results every time. This step is important for making high-quality parts with your press brake machine.

Material Properties

Thickness and Length

You must look at the thickness and length of your sheet metal. Thicker sheets need more force from the press brake machine. Thin sheets need less pressure to bend. The length of the sheet also changes the force needed. Longer sheets need more tonnage to bend right. You can use the formula P = 650 × S² × L / V to find the force. S means thickness, L means length, and V is the lower die opening width.

Tip: Always check thickness and length before you set up. This helps you avoid mistakes and keeps your bends correct.

The V-die opening you pick is important too. A wider opening means you need less force. But it can change the bend angle. If you use the wrong die, you might get cracks or bad bends. Sheet thickness is a big reason to change the tonnage. Thicker sheets need more pressure for the right angle and shape.

Type and Consistency

The kind of material you use changes how the machine works. Some metals, like stainless steel, are harder to bend than aluminum. Grain direction changes how the metal bends. If you bend against the grain, you might get cracks or rough edges. Hardness and stress inside the metal can make bending hard to control.

- Good, even materials give you better results.

- Same thickness and hardness help you get the same bend.

- Uneven stock can mess up your accuracy and repeatability.

If your material has different grain or hardness, you might get bad bends or broken parts. You should always check if your stock is the same all over. This helps you avoid problems like hydraulic drift or pressure issues. It also stops noisy operation. Using even materials gives you better results and more accuracy.

Note: Material consistency is very important for good bends. Always look at your stock before you start working.

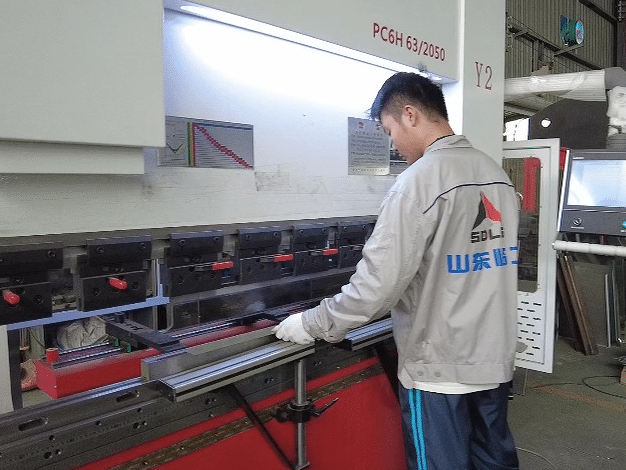

Operator Skill

Training

You are important for how well the press brake works. Training helps you use the machine safely. It also helps you get good results. When you learn all the features, you make fewer mistakes. You can also work faster. Good training teaches safety and how to use controls. It also shows you the best ways to work.

- Training lets you use the machine well from the start.

- If you are trained, you make fewer mistakes and stay safe.

- Learning good habits helps you do better work every day.

If you keep learning, you know new technology and methods. This helps you keep your skills sharp. It also helps you stay accurate.

Setup and Programming

Setting up and programming the press brake the right way saves time. It also helps you be more accurate. You should follow good steps to make work easier. This makes your work more reliable. Here are some tips for setup and programming:

- Use adjustable tooling for different thicknesses. This saves setup time.

- Clean and take care of your tools often.

- Use CNC programming to plan and test bends before you start.

- Plan your bends to change tools less often.

- Try new technology like AI programming and IoT systems for better results.

You can record your setup to find ways to save time. Work with engineers to make standard programs. Keep your tools organized to work faster and make fewer mistakes.

Efficiency

How well you work affects how many good parts you make. It also affects how fast you finish jobs. When you work well, you help your team reach goals. You also help keep customers happy. The table below shows how operator efficiency connects to quality and productivity:

| Metric | Description |

|---|---|

| Operator Efficiency | Shows how well you use your skills to get the most from the machine. |

| First Pass Yield (FPY) | Tells how many parts meet quality standards the first time. This lowers waste. |

| Overall Equipment Effectiveness (OEE) | Combines how often the machine runs, how well it works, and the quality of parts. |

If you have experience, you can use different press brakes with little retraining. Modern CNC systems make setup easier. You can focus on making parts and improving output. When you follow good steps, you help your shop get more work done and better quality.

Press Brake Machine Maintenance

Calibration

You should calibrate your press brake machine often. Calibration checks if the machine bends metal the right way. It makes sure the back gauge, ram, and tooling work together. If you skip calibration, your parts may have mistakes. Regular calibration helps you avoid waste and keeps your work safe.

Tip: Make a schedule for calibration. Do test bends to check accuracy before each new job.

The table below shows how different maintenance jobs help your machine:

| Maintenance Activity | Benefit |

|---|---|

| Routine Checks | Find small problems early |

| Cleaning | Stop dirt from getting in the system |

| Lubrication | Helps parts move smoothly and last longer |

| Component Replacement | Keeps the machine working well and stops breakdowns |

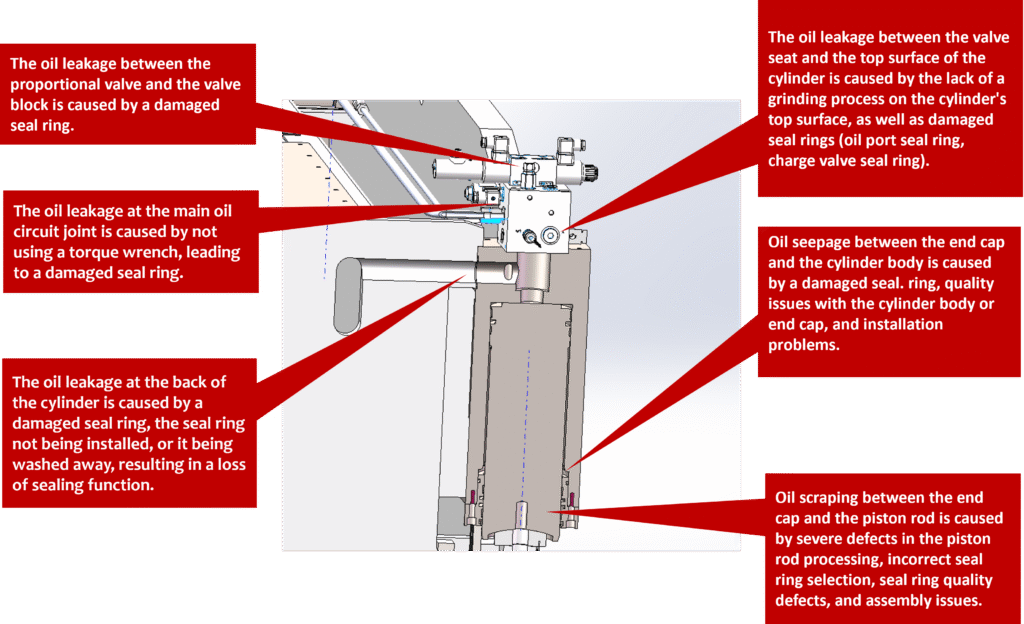

Cylinder Condition

You need to check the cylinders in your press brake machine. Broken cylinders can leak hydraulic fluid. You might see the press move unevenly or slowly. These problems make your work slower and can stop production. If you ignore cylinder damage, repairs can cost a lot or you may need a new machine.

- Broken cylinders can leak hydraulic fluid.

- You might see uneven press movement.

- Efficiency drops when cylinders break.

- Lots of damage can mean expensive repairs or replacement.

Look for leaks, odd sounds, or uneven movement. Change seals and old parts quickly. Good cylinders help your machine last longer.

Troubleshooting

You should know how to fix common problems. Quick fixes help you avoid long stops and keep work going. Here are some steps you can follow:

- If bends are not even: Check material, look at tooling, check CNC settings.

- If the machine can’t reach full tonnage: Change hydraulic pressure, check seals, check tonnage settings.

- If the back gauge is not straight: Clean tracks, recalibrate, check for wear.

- If the ram moves slowly or jumps: Remove air, change hydraulic fluid, check valves.

- If the control system has errors: Restart system, check sensors, update software.

- If there is too much noise or shaking: Tighten parts, remove air, change old parts.

- Preventive maintenance tips: Check hydraulic systems, tooling, back gauge calibration, and update software often.

Note: Regular maintenance helps you find problems early. You can fix small issues before they get worse.

When you follow a maintenance plan, you protect your press brake machine and stay safe. You also keep your work accurate and lower the chance of broken parts.

Environment and Power

Temperature

You should always watch the temperature in your workshop. When the temperature changes, it can affect how your press brake machine works. If it gets too hot or too cold, the hydraulic fluid inside the machine can change. This change in fluid thickness can make the force during bending less steady. You might notice that the bending angles are not always the same. You can check the pressure gauges to see if the pressure changes when the temperature goes up or down.

- Temperature changes can make hydraulic fluid thicker or thinner, which changes the bending force.

- Pressure gauges can show if the pressure is not steady, which can lead to bends that are not correct.

- High temperatures can also make brake pads wear out faster.

Tip: Keep your workshop at a steady temperature to help your machine stay accurate.

Cleanliness

A clean workspace helps your press brake machine last longer. Dust and dirt can build up on moving parts and sensors. This buildup can cause extra friction, which wears out parts faster. If you clean your machine often, you can stop these problems before they start. Cleaning also helps your machine run smoothly and keeps it from breaking down.

- Regular cleaning keeps your machine working well.

- Dust and debris can make parts wear out too soon.

- Clean machines have fewer problems and last longer.

Note: Make cleaning part of your daily routine to avoid costly repairs.

Power Stability

You need a steady power supply for your press brake machine. If the power goes up and down, the motors and control systems might not work right. Sometimes, the hydraulic pressure drops if the power is not steady. This can make the machine act in strange ways or even stop working for a while. Power problems can also make your energy bills go up and cause more pollution.

- Power changes can stop motors and controls from working right.

- Low or changing power can lower hydraulic pressure.

- Machines may act oddly or stop if the power is not stable.

- High energy use can lead to bigger bills and more greenhouse gases.

Tip: Use a power stabilizer or backup system to keep your machine running smoothly.

You get good results from your press brake if you care about how it is made. Make sure the machine is strong and built well. To keep it working, watch your tooling and materials. Operator skill is important too. Maintenance helps your machine last longer. Your work environment matters as well. Use these smart tips:

| Strategy | Benefit |

|---|---|

| Regular Cleaning | Stops breakdowns and helps your machine last |

| Operator Training | Lowers mistakes and helps you work faster |

| Advanced Technology | Makes bends more exact and saves time |

Learn about new technology and ways to work better. This helps you stay safe and do a good job every day.

FAQ

What is the most important factor for press brake accuracy?

The frame needs to be strong. A sturdy frame keeps the machine steady. This helps you get better accuracy. You will make fewer mistakes. Always look at the frame before starting a job.

How often should you calibrate your press brake machine?

Calibrate your press brake before every new job. Regular calibration helps you avoid mistakes. Monthly checks keep your machine working well.

Why does material consistency affect bending results?

Material consistency helps you get even bends. If your sheet metal is not the same thickness or hardness, you might see cracks or wrong angles. Always check your material before you start.

What safety features should you look for in a press brake?

You should look for light curtains, interlock systems, and sensors. These features stop the machine if something is wrong. Safety systems keep you and your team safe.

How can you improve operator efficiency?

You can get better efficiency with training, CNC controls, and organized tools. Good habits help you finish jobs faster and make fewer mistakes.