Press Brake Machine Troubleshooting: Common Causes of Oil Leakage and How to Fix Them

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

Hydraulic Press Brake Oil Leakages: Press Brake Machine Troubleshooting & Prevention

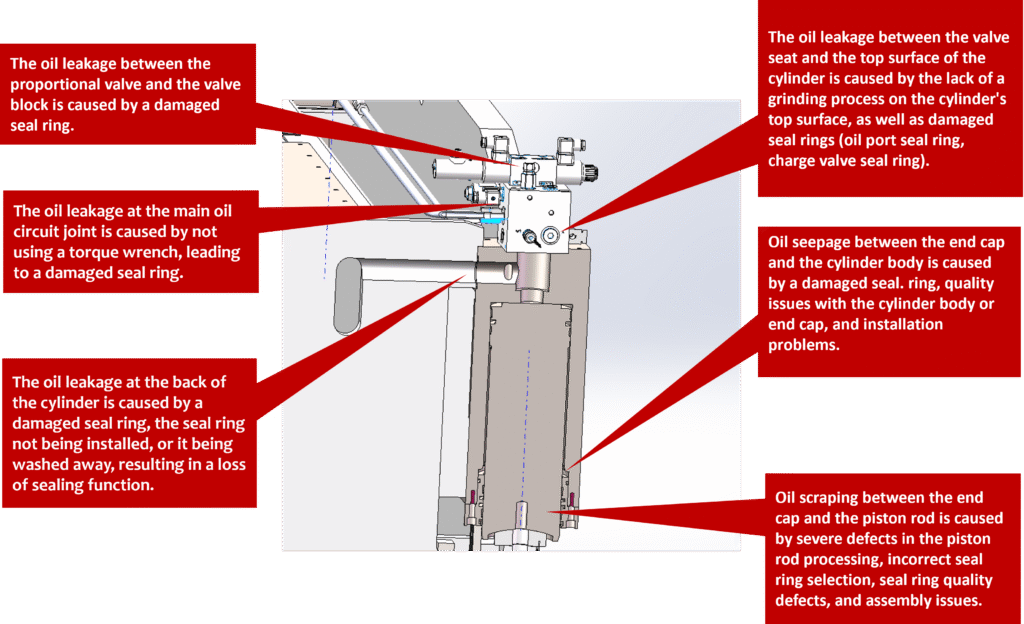

Hydraulic press brake machine troubleshooting often begins with addressing one of the most persistent issues in the shop: oil leakages. Hydraulic press brake oil leakages are critical issues that lead to machine downtime, product defects, and skyrocketing press brake machine maintenance costs. Identifying root causes and implementing targeted solutions is essential to maintaining optimal hydraulic system performance. In this article, we’ll walk through common oil leakage points—backed by visual diagrams and real-world press brake machine troubleshooting data—to provide actionable solutions for your facility.

1. Common Leakage Points for Press Brake Machine Maintenance

Effective press brake machine maintenance requires knowing exactly where to look when pressure drops or puddles appear. Based on our repair logs, we have highlighted several frequent leakage areas:

a. Proportional Valve and Valve Block

Issue: Damaged seal ring

Cause: Wear and tear or poor-quality sealing materials

Fix: Replace with high-quality or imported seal rings

b. Main Oil Circuit Joint

Issue: Seal ring damage due to improper assembly

Cause: Torque wrench not used during installation

Fix: Use calibrated torque tools during assembly to avoid over-tightening or under-tightening

c. Cylinder Back End

Issue: Oil leakage due to missing, damaged, or displaced seal ring

Fix: Ensure correct installation and use high-integrity seals that resist hydraulic wash-out

d. Valve Seat to Cylinder Top Surface

Issue: Improper machining and damaged seals

Cause: Missing grinding process on cylinder top; faulty oil port or charge valve seal rings

Fix: Add precision surface finishing and inspect seal quality

e. Cylinder Body and End Cap

Issue: Oil seepage

Cause: Poor installation, damaged seal ring, or poor-quality components

Fix: Improve component QC and ensure precise installation practices

f. Piston Rod and End Cap Interface

Issue: Oil scraping

Cause: Piston rod processing defects, incorrect seal type, seal quality issues

Fix: Select seals correctly, ensure high machining standards, and improve assembly procedures

2. Troubleshooting Table: Faults, Causes, and Solutions

We compiled the following data-driven table from real press brake maintenance logs to provide a quick reference:

| Faulty Components | Reasons | Solution |

|---|---|---|

| Valve group seal ring damaged | Poor seal ring quality | Request the supplier to replace with imported seal rings |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Lift valve damaged | Incorrect selection | Try a new type of lift valve |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Proportional valve damaged | Parameters Setting | Research valve characteristics and optimize system parameters |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Proportional pressure valve damaged | Set the correct parameters | Research valve characteristics and optimize system parameters |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Backpressure valve damaged | Measurement error in value setting | Test the backpressure standard value and promote it. |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Main and compensating cylinder seal rings damaged | Improper tolerance fitting | Optimize the tolerance fit between the end cap, piston rod, and seal ring |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness | |

| Filter seal ring damaged | Incorrect operation method | Require to apply lubricating oil when replacing the filter element. |

| Poor oil cleanliness | Locate the hydraulic oil contamination point and improve oil cleanliness |

3. How to Prevent Oil Leaks: Proactive Press Brake Machine Maintenance

Prevention is the most cost-effective form of press brake machine troubleshooting. Follow these industry best practices:

-

✔ Use High-Quality Seals: Always source seals from trusted manufacturers and inspect for defects before installation.

-

✔ Monitor Hydraulic Oil Cleanliness: Contaminated oil is a major cause of seal failure. Use filtration systems and conduct regular oil analysis as part of your press brake machine maintenance routine.

-

✔ Follow Precision Assembly Practices: Use torque wrenches, apply lubricants during filter installation, and ensure tolerance fits are within design specs.

-

✔ Test and Optimize Parameters: Backpressure, flow rates, and valve settings must be within optimal ranges for safe operation.

Conclusion

Most oil leaks stem from seal failures, poor component processing, or incorrect assembly methods. By adopting a systematic press brake machine troubleshooting approach and prioritizing preventive press brake machine maintenance, you can drastically reduce downtime and extend the lifespan of your machine.

Need professional help solving complex hydraulic issues? Contact our expert team for technical support or high-quality parts replacement to keep your shop running at peak precision.