How Press Brake Machine Manufacturers Select Hydraulic Pumps for Reliability & Accuracy

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

What Press Brake Machine Manufacturers Really Consider When Selecting Hydraulic Pumps

For a professional press brake machine manufacturer, hydraulic pump selection is never about choosing a brand for marketing purposes. Instead, it is a core engineering decision that directly affects bending accuracy, machine stability, service life, and total cost of ownership.

In real product development, manufacturers often evaluate multiple hydraulic pump solutions in parallel, including well-known options such as HAWE, VOITH, or Eckerle. However, regardless of the final choice, the engineering logic behind the decision remains consistent.

This article explains hydraulic pump selection from the real-world perspective of press brake manufacturers, focusing on the technical factors that truly matter in long-term production environments.

Why Hydraulic Pump Selection Matters to a Press Brake Machine Manufacturer

A press brake’s hydraulic system is not an isolated component—it interacts directly with the frame, ram, tooling, CNC control, and compensation system. For this reason, hydraulic pump performance has a direct impact on:

-

Ram motion controllability

-

Bending angle consistency

-

Thermal stability of the hydraulic system

-

Overall machine reliability over years of operation

An experienced press brake machine manufacturer understands that pump selection reflects the manufacturer’s engineering capability, not just its supplier list.

Rated Pressure and Stability Under Real Bending Loads

Long-term stability matters more than peak specifications

In actual production, press brakes rarely reach maximum pressure only for brief moments. Instead, they often operate continuously near rated tonnage, especially in applications such as:

-

Thick plate bending

-

High-strength materials (high-yield steel, stainless steel)

-

Full-length bending on long worktables

For this reason, manufacturers focus on:

-

Stable operation at rated working pressure

-

Low pressure fluctuation and pulsation

-

Minimal efficiency loss under sustained high load

From an engineering standpoint, pressure stability directly determines:

-

Ram movement controllability

-

Angle consistency during the holding phase

-

Whether CNC crowning and compensation algorithms can function reliably

Matching Pump Flow Characteristics to the Actual Bending Process

Bigger flow is not better—correct flow is

Press brake motion consists of several distinct operating stages:

-

Rapid approach (idle stroke)

-

Working bending stroke

-

Pressure holding

-

Return stroke

Each stage requires different flow characteristics. Therefore, manufacturers carefully evaluate hydraulic pump performance in terms of:

-

Stability during low-speed, high-torque operation

-

Efficiency under small-flow conditions

-

Compatibility with energy-saving system designs

This is why a single press brake machine manufacturer may use different pump types—such as gear pumps, internal gear pumps, or radial piston pumps—across different machine series and tonnage ranges.

Thermal Performance and Oil Temperature Control

Oil temperature is a hidden but critical reliability indicator

In multi-shift or continuous production environments, excessive heat is one of the most common causes of hydraulic system issues. When selecting pumps, manufacturers pay close attention to:

-

Internal leakage characteristics

-

Efficiency variation under high-pressure conditions

-

Long-term impact on hydraulic oil temperature

Good thermal performance results in:

-

Longer hydraulic oil service life

-

Slower seal aging

-

More stable operation of valves and cylinders

This is why mid- to high-end press brake designs often favor pump solutions that generate less heat under continuous high-pressure operation, rather than simply comparing initial purchase prices.

Noise, Vibration, and Their Impact on Machine Structure

From the user’s perspective, noise and vibration are often perceived as indicators of overall machine quality. From the manufacturer’s perspective, they also affect:

-

Structural fatigue of the press brake frame

-

Hydraulic piping lifespan

-

Long-term system stability

A stable hydraulic pump with low pressure pulsation helps reduce resonance throughout the hydraulic system and frame, contributing to smoother operation and longer machine life—especially in high-precision bending applications.

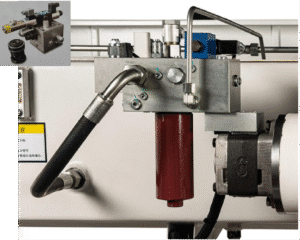

System Compatibility and Design Flexibility

The pump should support the system—not limit it

When designing a complete hydraulic system, a professional press brake machine manufacturer expects the pump to offer:

-

Clear and predictable performance boundaries

-

Strong compatibility with valve blocks and CNC control systems

-

Adequate safety margins across different applications

These factors directly influence:

-

System layout and compactness

-

Feasibility of future upgrades (such as servo-hydraulic solutions)

-

Scalability of platform-based press brake designs

Total Cost of Ownership Over the Machine’s Lifecycle

Rather than focusing on initial purchase price alone, experienced manufacturers evaluate hydraulic pump solutions from a Total Cost of Ownership (TCO) perspective, including:

-

Failure rates

-

Maintenance frequency

-

Spare parts availability

-

Impact on after-sales service costs

In many cases, a pump with a higher initial cost but superior long-term stability significantly reduces overall machine cost over a 5–10 year service life. This is why economy, standard, and high-precision press brake models often adopt different hydraulic configurations within the same product portfolio.

Why Brand Is the Result, Not the Starting Point

Based on the engineering principles above, reliable hydraulic pump brands such as HAWE or VOITH are commonly included in manufacturer evaluations. However, brand selection is always the final outcome, not the starting point.

The real deciding factors remain:

-

Actual operating conditions

-

Design objectives

-

Market positioning

-

End-user application requirements

For customers, choosing a professional press brake machine manufacturer or a press brake machine supplier means selecting a partner who understands real bending loads, applies rational engineering judgment, and balances reliability, performance, and cost—rather than simply promoting component brands.

Premium Press Brake with High Performance

Conclusion: Hydraulic Pump Selection Reflects Manufacturing Expertise

Hydraulic pump selection is one of the clearest indicators of a press brake manufacturer’s engineering capability. It reflects how well the manufacturer understands bending processes, system integration, and long-term machine performance.

A well-designed hydraulic system is not about using the most expensive components—it is about using the right components for the right application, supported by sound engineering decisions.