Press Brake Machine Manufacturer Guide: Noise Standards, Limits & Testing Methods (dB(A))

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

Press Brake Machine Manufacturer Guide: Noise Standards, Limits & Testing Methods (dB(A))

For any press brake machine manufacturer, machine noise control is not only a matter of regulatory compliance, but also a key indicator of hydraulic system design quality, mechanical rigidity, and overall manufacturing standards.

This document outlines internationally referenced noise limit standards and measurement requirements applicable to press brake machines, serving as a technical guideline for manufacturers and industrial users.

| Type of Indicator | Typical Limit Requirement | Remarks |

|---|

| No-load operating noise | ≤ 75–80 dB(A) | Modern hydraulic systems (e.g. with servo pumps or high-performance valve groups) can typically achieve levels below 75 dB(A). |

| Instantaneous noise during bending under load | ≤ 85 dB(A) | Transient impact noise. If it exceeds 85 dB(A), a “Hearing Protection Required” warning label must be affixed to the machine. |

| Occupational exposure limit (OSHA / NIOSH) | 85 dB(A) / 8 hours | Applicable to operator workstations. If ambient noise exceeds this limit, the company must implement a hearing conservation program. |

1 Scope

This standard specifies the noise limit values for sound power levels and sound pressure levels of press brake machines.

This standard applies to press brake machines, including various types of sheet metal press brake machines and folding machines.

2 Normative References

The following documents contain provisions which, through reference in this standard, constitute provisions of this standard. For dated references, any subsequent amendments (excluding corrigenda) or revisions do not apply to this standard. However, parties that have reached agreements based on this standard are encouraged to investigate the possibility of using the latest editions of these documents. For undated references, the latest editions apply.

- GB/T 23281—2009

Measurement methods of sound pressure levels for forging and pressing machinery - GB/T 23282—2009

Measurement methods of sound power levels for forging and pressing machinery

3 Press Brake Machine Noise Limits

The noise of press brake machines is classified into sound power level and sound pressure level requirements. Noise limit values are specified according to different types of press brake machines.

3.1 Noise Limits for Sheet Metal Press Brake Machines

3.1.1 Sound Power Level Limits for Sheet Metal Press Brake Machines

During continuous no-load operation, the A-weighted sound power level (LWA) of sheet metal press brake machines shall not exceed the values specified in Table 1

Table1

| Transmission Type | Nominal Force/kN | Sound Power Level Limit LWA /dB(A) |

| Mechanical drive | ≤630 | 100 |

| >630~2500 | 110 | |

| Hydraulic drive | ≤630 | 95 |

| >630~2500 | 100 | |

| >2500 | 105 |

3.1.2 Sound Pressure Level Limits for Sheet Metal Press Brake Machines

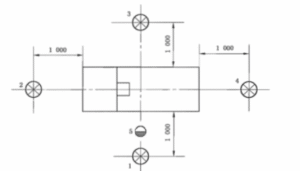

During continuous no-load operation, the A-weighted sound pressure level (LpA) measured at the specified positions of a sheet metal press brake machine shall not exceed the values specified in Table 2.

Table2

| Transmission Type | Nominal Force/kN | Sound Power Level Limit LpA /dB(A) |

| Mechanical drive | ≤630 | 85 |

| >630~2500 | 90 | |

| Hydraulic drive | ≤630 | 82 |

| >630~2500 | 85 | |

| >2500 | 88 |

3.1.3 Impulse Noise Sound Pressure Level of Press Brake Machines

For mechanically driven press brake machines, during a single stroke under no-load operation, the A-weighted impulse sound pressure level (LpAI) measured at the specified positions shall not exceed the limits specified in Table 3.

Table3

| Nominal Force/kN | Sound Power Level Limit LpAI /dB(A) |

| ≤630 | 95 |

| >630~2500 | 100 |

FAQ: Noise Standards and Press Brake Machine Manufacturers

Q1: Why should a press brake machine manufacturer strictly comply with noise limit standards?

For a professional press brake machine manufacturer, noise compliance is not only a regulatory requirement but also an indicator of overall machine design quality.

Meeting defined noise limits reflects proper hydraulic system matching, stable pressure control, and effective vibration management—factors that directly affect long-term machine reliability and operator safety.

Q2: How do press brake machine manufacturers typically reduce operating noise?

Most experienced press brake machine manufacturers focus on system-level optimization rather than isolated components, including:

-

Stable hydraulic pressure and flow control

-

Reduced pressure pulsation in valve groups

-

Optimized mechanical structure and damping

-

Proper layout of hydraulic pipelines and mounting points

Noise performance is therefore the result of engineering integration, not a single design choice.

Q3: Is lower noise always an indicator of higher press brake quality?

While noise alone should not be the only evaluation criterion, many buyers consider it a practical reference when comparing different press brake machine manufacturers.

Machines that operate within lower noise ranges often demonstrate better system stability, reduced wear, and improved long-term consistency.

Q4: Do noise standards affect press brake selection for different applications?

Yes. Reputable press brake machine manufacturers consider noise limits early in the design phase, especially for:

-

Continuous production environments

-

Multi-shift operation

-

Workshops with strict occupational health requirements

Early compliance helps avoid retrofitting, additional soundproofing, or operational restrictions after installation.

Q5: What should buyers ask a press brake machine manufacturer regarding noise performance?

When evaluating suppliers, buyers may ask:

-

Under which operating conditions was noise measured?

-

Whether measurements follow recognized standards (e.g. GB/T, ISO)

-

Typical no-load and load noise levels at operator positions

A professional press brake machine manufacturer should be able to provide clear, standard-based explanations rather than marketing descriptions.