6 Aixs

Customize Your Press Brake Product

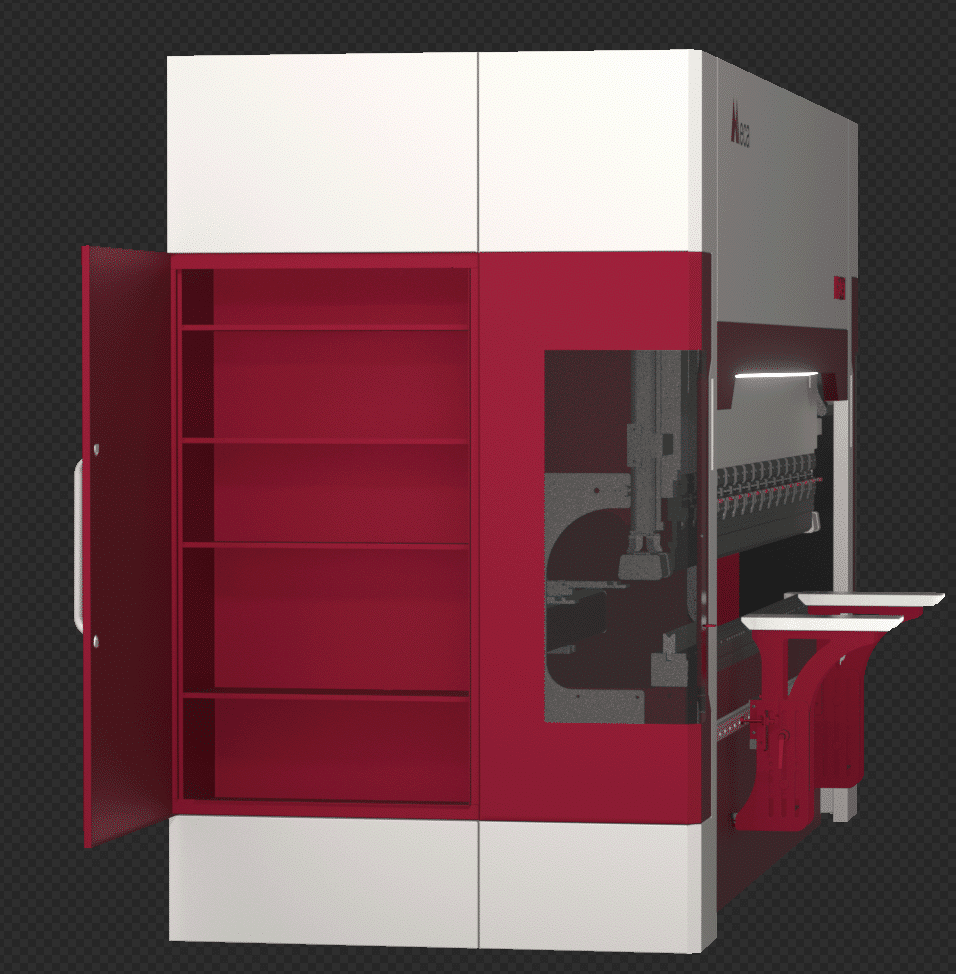

The H series offers a customized appearance, allowing you to match your brand colors and logo.

Highlights of Our CNC Press Brake

High Precision

Precision improved by:

- Servo motor + magnetic grating scale closed-loop control

- Bidirectional mechanical deflection compensation

- V-opening deformation compensation

- Optional hydraulic automatic clamping system

Energy Saving

Asynchronous Motors :

Run continuously, with fixed energy consumption (e.g., a 10kW motor’s standby power consumption accounts for 30%).

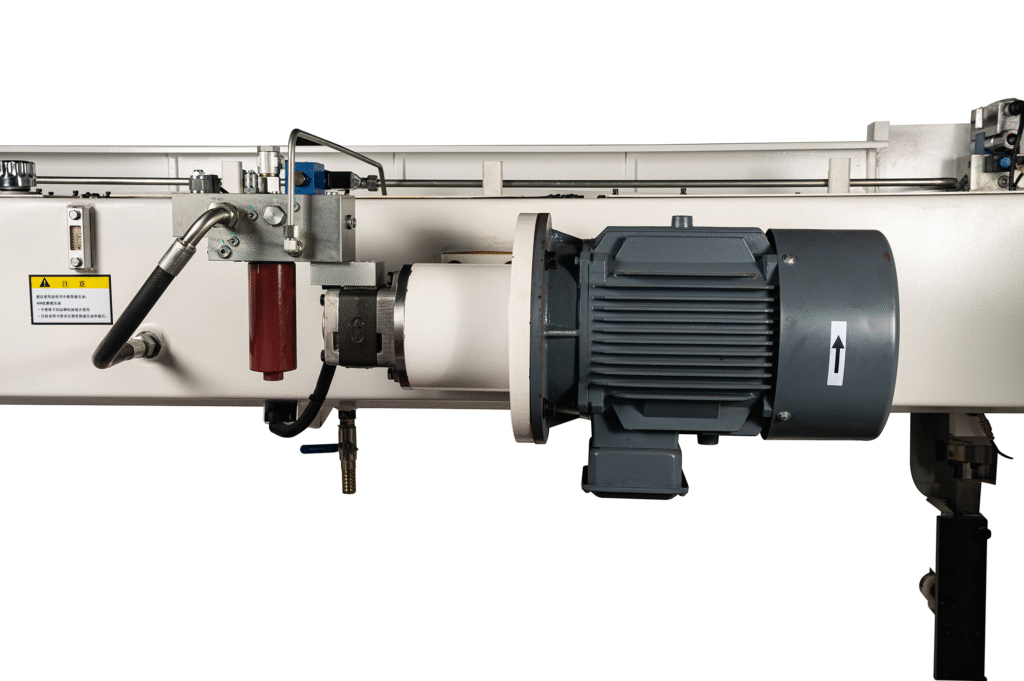

Servo Motors

Consume power only when operating, achieving over 40% energy savings. Save at least $1,000 annually ($0.17 per kWh*10h/per day).

Safety Guarantee

Standard

- Side safety guard doors

- Remote-controlled roll-up rear door

- Emergency switch on foot pedal

Optional (CE certificate):

- Laser safety light curtain

- 5-point monitored hydraulic valve

Attractive Design

Standard

- Closable protective cover

- Acrylic viewing window at the DSP position

- Built-in tool cabinet

- Front supports with strong load-bearing capacity

- Aluminum remote control roller shutter door

Optional :

- Resistance Surface (with bristles) in Front Support

- Customized Logo and Color

The CNC press brake frame and components are designed using advanced 3D modeling and finite element analysis (FEA) simulation. The frame features an integrated steel plate welded structure, offering exceptional strength, excellent rigidity, and robust resistance to torsional deformation. To eliminate internal stress and ensure long-term precision stability, the entire frame undergoes shot blasting and other stress-relief treatments, enhancing the machine’s performance and longevity.

The steel plates used for the machine frame are thicker than those of similar products on the market, providing superior overall rigidity and significantly reducing deformation accumulation over long-term use. A robust frame offers a stable foundation for the synchronized movement of the ram, ensuring precise synchronization accuracy on both sides. During rapid descent or stamping operations, the thicker frame effectively absorbs vibrations, minimizing relative displacement between the workpiece and tooling, thus maintaining machining accuracy.

The oil pump of cnc press brake is powered by ESTUN servo motor, enabling precise control of speed and flow for adjustable operation. Under the same process conditions, return height, and operator speed, productivity increases by 10% per unit time. Noise levels are reduced by 7dB compared to standard machines. It also cuts energy consumption by up to 50%, with even greater savings during idle periods, such as workpiece repositioning. Additionally, it minimizes heat generation, reducing wear on hydraulic components and extending the machine’s lifespan.

German Hawe hydraulic control technology ensures high synchronization precision.

The machine can operate continuously for 8 hours under rated load, with stable and precise hydraulic system performance, and oil temperature maintained within international standard limits.

The oil pump is a high-pressure internal gear pump, capable of withstanding high pressure with low noise.The system features overload pressure relief protection for enhanced safety and reliability.It includes two-stage filtration—coarse and fine—with high filtration precision.The high-pressure filter is equipped with a clogging indicator.

An intuitive and clear oil level display is provided.Modular technology is used for a compact structure, excellent sealing performance, easy maintenance, and long service life.The hydraulic piping system consists of Parker-type ferrule fittings and seamless steel pipes, ensuring leak-free operation and cleanliness.

Sturdy and Reliable: Crafted from premium forged materials (45# steel, fully forged) and subjected to rigorous heat treatment (annealing, normalizing, and quenching).

Precision and Durability: Achieved with advanced machining technology (CNC gantry milling), critical surface enhancement techniques (rolling, honing, copper infusion, chrome plating, and polishing) to ensure high precision, hardness, excellent surface finish, and superior wear and corrosion resistance.

Superior Sealing: Integrated flow channels minimize leak points, while the high precision and special treatment (copper infusion) of key mating surfaces (inner holes, guide surfaces) provide a strong foundation for optimal sealing.

Contamination-Free: All parts are ultrasonically cleaned after machining to completely remove residue and metal filings, preventing “scoring” during assembly. High-pressure oil lines are thoroughly cleaned to avoid contamination, protecting hydraulic valves and cylinders and eliminating contamination-related failures from the outset.

Quality Assurance: Non-destructive testing, precision machining, and stringent pressure retention tests ensure the final product meets the highest quality standards.

The main electrical components are from the Schneider brand, ensuring safety, reliability, long service life, and strong anti-interference capabilities. The control station is equipped with a movable footswitch, offering functions such as power on and emergency stop. The wiring of the electrical cabinet is reasonable and clear, making maintenance or troubleshooting easier, while also providing excellent heat dissipation.

The electrical setup complies with CE certification requirements for optional configuration.

The entire range of rear material blocking beams features a dual rail design, effectively reducing beam shake.It uses well-known brands for linear guides (Taiwan HIWIN) and ball screws (Taiwan HIWIN), ensuring high positioning accuracy.The guide rail and screw diameter are ≥20mm (Linear Rail PMI 25mm, Ball screw PMI 20mm).

- 4+1 Axis:Y1、Y2、X、R、+V;

- 6+1 Axis:Y1、Y2、X、R、Z1、Z2、+V;

The X-axis is the control axis for the rear backgauge. It uses a servo motor combined with a precision ball screw drive and linear ball guide rails, achieving a positioning accuracy of ≤±0.1 mm. This ensures that the two material stops remain synchronized during movement, thereby guaranteeing the accuracy of the workpiece.

The R-axis controls the vertical movement of the rear backgauge. It utilizes a servo motor with a precision rack drive and precision guide rods for upper and lower support guidance, achieving a vertical positioning accuracy of ≤±0.1 mm. This ensures synchronized vertical motion of the backgauge and maintains workpiece accuracy.

The backgauge guide rail seats, crossbeam, and material stoppers are distributed on both sides using large channel steel, providing better rigidity, impact resistance, and extended service life.

The guide rail seats use ground ball screws, which offer excellent wear resistance, high repeatability, and positioning accuracy.

A synchronous belt structure is used, enabling high-speed operation with low noise, fast movement, and high precision.

The CNC system calculates the required compensation based on the load force during bending, which causes deflection in the ram and table side plates. It then automatically adjusts a convex wedge block to offset this deflection. By positioning wedge blocks to form a curve matching the actual deflection, it keeps the die gap uniform and ensures consistent bending angles along the workpiece. This mechanical compensation is precise, stable, and maintenance-free, unlike hydraulic systems. Multiple compensation points allow for smoother correction, improving bending accuracy. Driven by a motor and controlled as a CNC axis, it enables precise digital adjustments.

This press brake equipped with bi–directional mechanical crowing system. The compensation wedge consists of upper and lower plates, each with several pairs of wave-shaped inclined surfaces of varying angles, ensuring high matching precision.By moving the upper and lower wave-shaped wedges relative to each other along the length direction, a compensation curve is generated to counteract deflection deformation of the press brake during bending.The lower compensation wedge adopts an integrated wave-shaped inclined surface structure, providing stable compensation with no repeat positioning error.

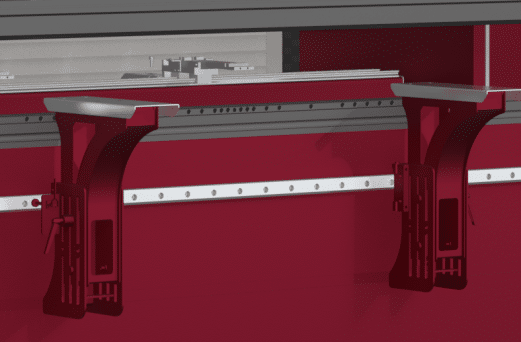

- The widened front support mechanism has excellent load-bearing capacity and strong compatibility with both thin and thick plates.

- Horizontal guiding on linear rail & easy height adjustment with a hand wheel

- Optional resistance surface structure

Built-in tool cabinet, can hold rulers and other commonly tools

The standard configuration uses the DELEM DA-53T CNC system

- 2D touch screen graphic simulation.

- 3D visualization in production mode O 17″TFT color display

- Memory capacity 1 GB

- USB interfacing

DELEM DA-66T/ DELEM DA-69T For Optional

The control station is equipped with a movable foot switch, offering functions such as power on and emergency stop.

Standard Configuration: Dual foot pedals

Optional Configuration

Configuration Selection Guide

| Configuration | √Standard ❏Options | Configuration | √Standard ❏Options |

|---|---|---|---|

| Axis | √ 4+1 | Crowning System | √ HSSR Bi-directional Compensation |

| ❏ 6+1 | Hydraulic Cylinder | √ Shuheng | |

| CNC System | √ DELEM DA-53T | Sealing Components | √ PARKER |

| ❏ DELEM DA-66T | Foot Pedal | ❏ Single foot pedal | |

| ❏ DELEM DA-69T | ❏ Double foot pedal | ||

| ❏ Cybelec CT15 | LED Light | √ LED lights on both front and back | |

| Servo Main Motor | √ ESTUN | Punch Clamp | √ High Quality Manual Clamp |

| Hydraulic System | √ Germany HAWE | ❏ Hydraulic Automatic Clamping Device | |

| ❏3-Point Monitoring Safety Pressure Valve | Die Clamp | √2V-'T’Quick Change Bottom | |

| ❏5-Point Monitoring Safety Pressure Valve (CE) | Toolings | √Promecam Punch 85° | |

| Magnetic Scale | √ Italy GIVI | √ 2V 39 mm Die | |

| Linear Guide Rail | √ Taiwan HIWIN | ❏4V 60mm Die | |

| Ball Screw | √ Taiwan HIWIN, Diameter not less than 20mm | ❏Customized Toolings | |

| Oil Pump | √ HAWE | Rear Protective Door | ❏ Electric Auto Alu Roll-up Door |

| Servo Motor (back gauge) | √ ESTUN | Safety Light Curtain | ❏DSP-AP+MCS |

| Servo Drive (back gauge) | √ ESTUN | ❏AKAS lc2m+FMSC | |

| High-Pressure Pipeline | √ PARKER | ❏AKAS lc2m+GMSA (Contain speed monitoring) | |

| AC Contactor | √ Schneider | CE | ❏Electrical Setup & CE certificate |

Standard Model

Request a Technical Proposal Now!

FAQ

What models are available for your press brake products?

Our standard models include:50t/1500mm, 110t/3100mm, 170t/3100mm, 220t/3100mm, 110t/4100mm, 170t/4100mm, 220t/4100mm, 320t/4100mm. Other models can be customized.

Can you provide tandem press brake?

Yes, we can. 170t/3100mm and 220t/3100mm are the tandem press brake we make most often.

Can I customize my own brand?

Yes, We can design the appearance and color scheme according to your brand requirements.

What is your delivery lead time?

The lead time for standard models is 45-50 days, and for custom products, it is 60-70 days.

I need CE certification. Can you provide it?

Yes. We can make electrical safety settings for the system according to CE requirements and provide the CE certificate.

I am an end user, and I’m not sure how to choose the right press brake for my needs. Can you provide recommendations?

If you can describe the materials you bend regularly, including the material type, thickness, or provide a workpiece drawing, our engineers will assist you in selecting the right model.

Do you offer a warranty?

We promise one-year warranty. During this period, any quality issues with parts caused by factors other than human error can be repaired or replaced free of charge. However, you will need to cover the shipping costs both ways.

How do you provide after-sales service?

After both parties sign the sales contract, based on the specific requirements of the customer, free remote video guidance and training could be provided.The training content includes:

- Principles and introduction of the CNC press brake.

- System components of the CNC press brake.

- Operation of the CNC press brake.

- Maintenance of the CNC press brake.

- Solutions for common issue

If you need a on-site service, you shall provide round-trip airfare, accommodation, and a daily allowance of the engineer.