6 ejes

Plegadora hidráulica rentable

Consultar precioHighlights of M-series CNC Press Brake

High Precision

Precision improved by:

- Servo motor + magnetic grating scale closed-loop control

- Bidirectional mechanical deflection compensation

- V-opening deformation compensation

- Optional hydraulic automatic clamping system

Multiple Models

- The product models range from 60t/2050mm to 600t/6100mm

- Professional transportation solutions for large-tonnage machines

- Tandem press brake solution can be customized

Energy Efficiency

Asynchronous Motors :

Run continuously, with fixed energy consumption (e.g., a 10kW motor’s standby power consumption accounts for 30%).

Servo Motors

Consume power only when operating, achieving over 40% energy savings. Save at least $1,000 annually ($0.17 per kWh*10h/per day).

Safety Guarantee

Standard

- Side safety guard doors

- Remote-controlled roll-up rear door

- Emergency switch on foot pedal

Optional (CE certificate):

- Laser safety light curtain

- 5-point monitored hydraulic valve

The CNC press brake frame and components are designed using advanced 3D modeling and finite element analysis (FEA) simulation. The frame features an integrated steel plate welded structure, offering exceptional strength, excellent rigidity, and robust resistance to torsional deformation. To eliminate internal stress and ensure long-term precision stability, the entire frame undergoes shot blasting and other stress-relief treatments, enhancing the machine’s performance and longevity.

The steel plates used for the machine frame are thicker than those of similar products on the market, providing superior overall rigidity and significantly reducing deformation accumulation over long-term use. A robust frame offers a stable foundation for the synchronized movement of the ram, ensuring precise synchronization accuracy on both sides. During rapid descent or stamping operations, the thicker frame effectively absorbs vibrations, minimizing relative displacement between the workpiece and tooling, thus maintaining machining accuracy.

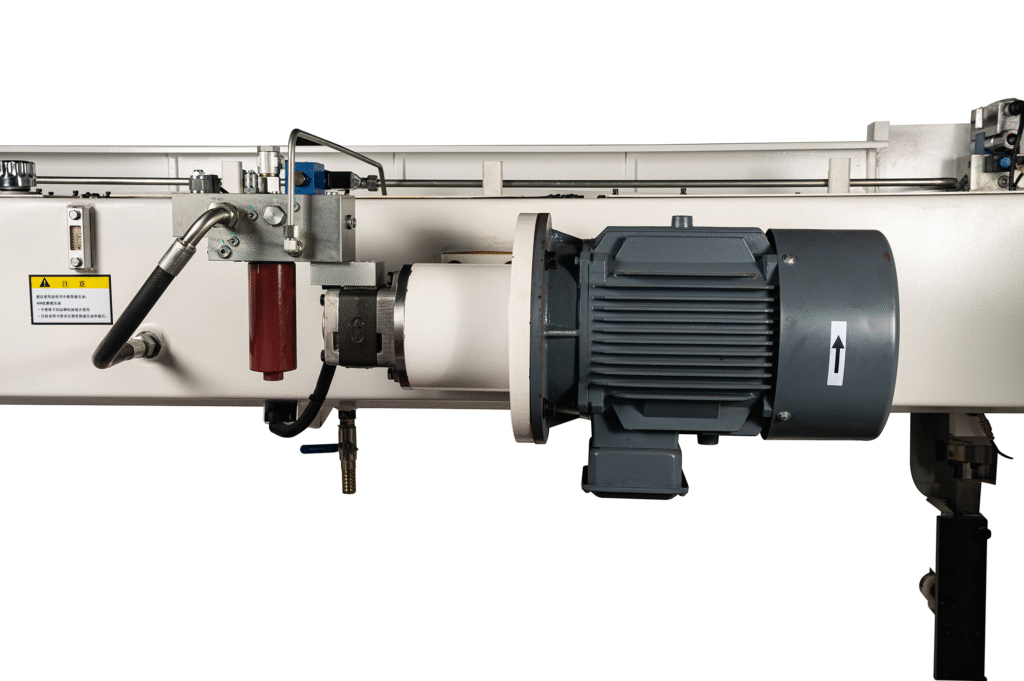

The oil pump of cnc press brake is powered by ESTUN servo motor, enabling precise control of speed and flow for adjustable operation. Under the same process conditions, return height, and operator speed, productivity increases by 10% per unit time. Noise levels are reduced by 7dB compared to standard machines. It also cuts energy consumption by up to 50%, with even greater savings during idle periods, such as workpiece repositioning. Additionally, it minimizes heat generation, reducing wear on hydraulic components and extending the machine’s lifespan.

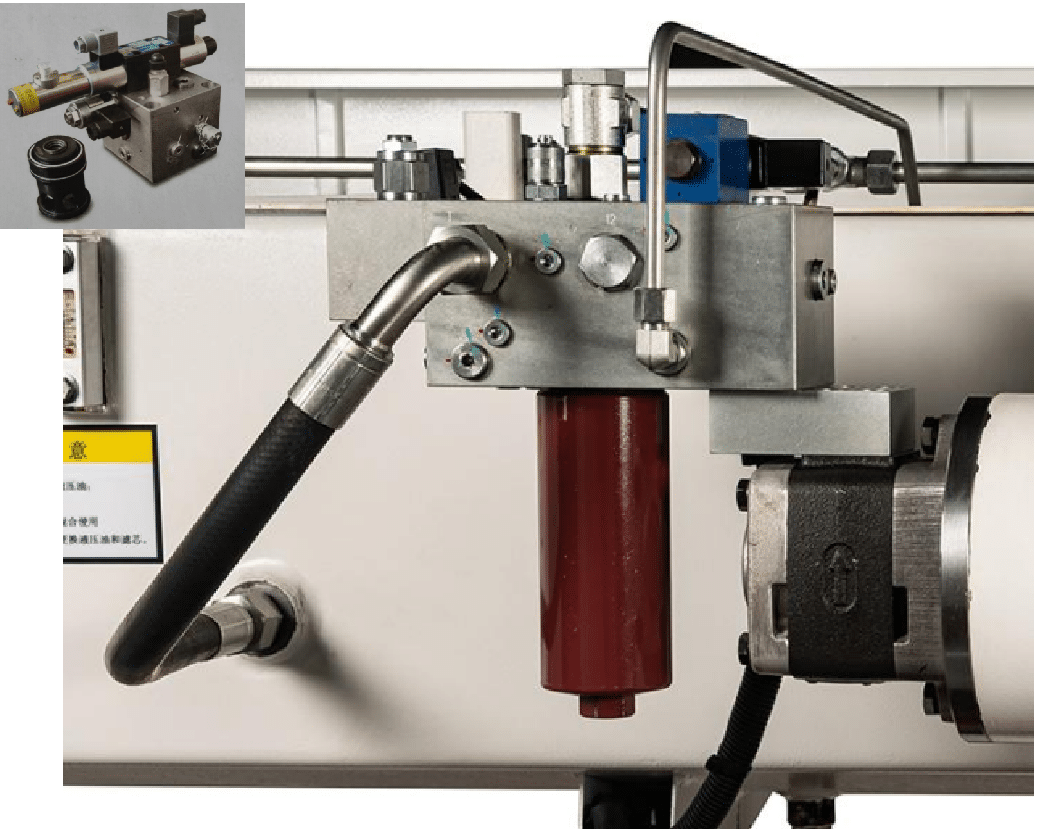

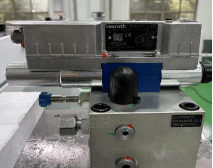

- The system adopts world-leading German Rexroth hydraulic control technology, achieving extremely high synchronization control accuracy.

- The oil pump uses Le high-pressure internal gear pumps, capable of withstanding high pressure and operating with low noise.

- The hydraulic system features overload relief protection, ensuring safety and reliability.

- The hydraulic system includes two-stage filtration, with high filtration precision.

- The high-pressure filter is equipped with a clogging indicator function.

- There is a clear and intuitive oil level height display.

- Modular technology is used, ensuring a compact structure, strong sealing performance, easy maintenance, and long service life.

- The hydraulic piping system consists of Parker-type ferrule fittings and seamless steel pipes, ensuring leak-free operation and cleanliness.

Sturdy and Reliable: Crafted from premium forged materials (45# steel, fully forged) and subjected to rigorous heat treatment (annealing, normalizing, and quenching).

Precision and Durability: Achieved with advanced machining technology (CNC gantry milling), critical surface enhancement techniques (rolling, honing, copper infusion, chrome plating, and polishing) to ensure high precision, hardness, excellent surface finish, and superior wear and corrosion resistance.

Superior Sealing: Integrated flow channels minimize leak points, while the high precision and special treatment (copper infusion) of key mating surfaces (inner holes, guide surfaces) provide a strong foundation for optimal sealing.

Contamination-Free: All parts are ultrasonically cleaned after machining to completely remove residue and metal filings, preventing “scoring” during assembly. High-pressure oil lines are thoroughly cleaned to avoid contamination, protecting hydraulic valves and cylinders and eliminating contamination-related failures from the outset.

Quality Assurance: Non-destructive testing, precision machining, and stringent pressure retention tests ensure the final product meets the highest quality standards.

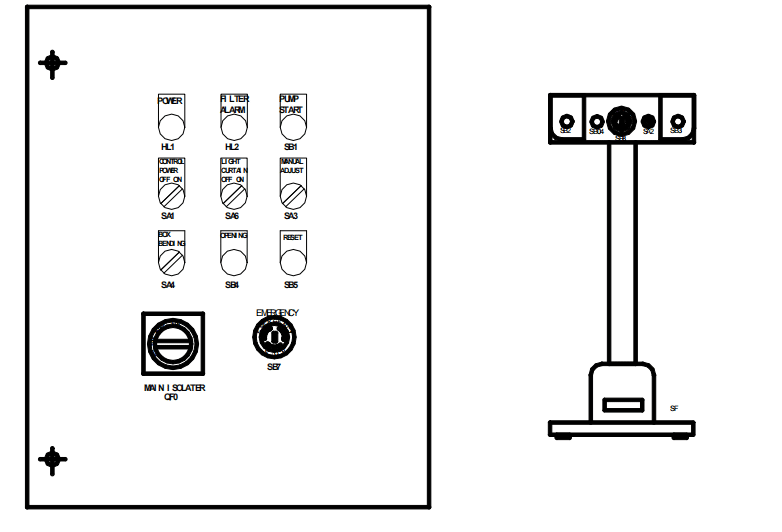

The main electrical components are from the Schneider brand, ensuring safety, reliability, long service life, and strong anti-interference capabilities. The control station is equipped with a movable footswitch, offering functions such as power on and emergency stop. The wiring of the electrical cabinet is reasonable and clear, making maintenance or troubleshooting easier, while also providing excellent heat dissipation.

The electrical setup complies with CE certification requirements for optional configuration.

The entire range of rear material blocking beams features a dual rail design, effectively reducing beam shake.It uses well-known brands for linear guides (Taiwan HIWIN) and ball screws (Taiwan HIWIN), ensuring high positioning accuracy.The guide rail and screw diameter are ≥20mm (Linear Rail PMI 25mm, Ball screw PMI 20mm).

- 4+1 Axis:Y1、Y2、X、R、+V;

- 6+1 Axis:Y1、Y2、X、R、Z1、Z2、+V;

-

The X-axis is the control axis for the rear backgauge. It uses a servo motor combined with a precision ball screw drive and linear ball guide rails, achieving a positioning accuracy of ≤±0.1 mm. This ensures that the two material stops remain synchronized during movement, thereby guaranteeing the accuracy of the workpiece.

-

The R-axis controls the vertical movement of the rear backgauge. It utilizes a servo motor with a precision rack drive and precision guide rods for upper and lower support guidance, achieving a vertical positioning accuracy of ≤±0.1 mm. This ensures synchronized vertical motion of the backgauge and maintains workpiece accuracy.

-

The backgauge guide rail seats, crossbeam, and material stoppers are distributed on both sides using large channel steel, providing better rigidity, impact resistance, and extended service life.

-

The guide rail seats use ground ball screws, which offer excellent wear resistance, high repeatability, and positioning accuracy.

-

A synchronous belt structure is used, enabling high-speed operation with low noise, fast movement, and high precision.

The CNC system calculates the required compensation based on the load force during bending, which causes deflection in the ram and table side plates. It then automatically adjusts a convex wedge block to offset this deflection. By positioning wedge blocks to form a curve matching the actual deflection, it keeps the die gap uniform and ensures consistent bending angles along the workpiece. This mechanical compensation is precise, stable, and maintenance-free, unlike hydraulic systems. Multiple compensation points allow for smoother correction, improving bending accuracy. Driven by a motor and controlled as a CNC axis, it enables precise digital adjustments.

- The front supportercan slide along a linear guide rail, allowing the spacing to be adjusted according to the length of the workpiece.

- The supporter can be rotated and folded parallel to the press brake worktable, making it convenient for transportation and storage.

-

Accurately measure the deformation and provide feedback compensation to ensure the bending accuracy. Effectively prevent non-standard workpieces from colliding with the interference detection unit

The standard configuration for 4+1 Axis use DELEM DA-53T CNC system

- 2D touch screen graphic simulation.

- 3D visualization in production mode O 17″TFT color display

- Memory capacity 1 GB

- USB interfacing

4+1 Optional:

- Cybtouch CT 12

- ESA 840

6+1 Optional:

- DELEM DA-66T

- DELEM DA-69T

- ESA 840

Configuración opcional

Guía de selección de configuración de la plegadora hidráulica

| Configuration | √Standard ❏Options | Configuration | √Standard ❏Options |

|---|---|---|---|

| Axis | √ 4+1 | Crowning System | √ Mechanical Compensation Motorized by CNC |

| ❏ 6+1 | Sealing Components | √ PARKER | |

| 4+1 CNC System | √ DELEM DA-53T | Foot Pedal | √ Double foot pedal (Non CE) |

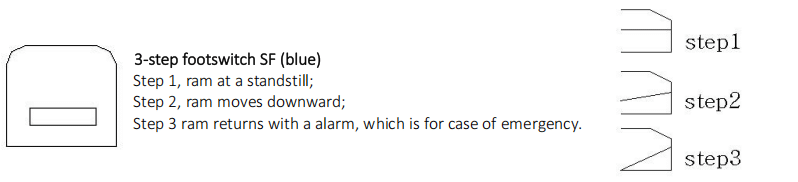

| ❏ Cybelec CT 12 | ❏ Single 3-step foot switch comply with CE Step1,ramata stand still; Step2,rammoves downward; Step3,ram returns with a alarm, which is for case of emergency. |

||

| ❏ ESA 840 | |||

| 6+1 CNC System | ❏ DELEM DA-66T | ||

| ❏ DELEM DA-69T | LED Light | √ LED lights on both front and back | |

| ❏ Cybelec CT15 | Punch Clamp | √ High Quality Manual Clamp | |

| ❏ ESA 840 | ❏ Hydraulic Automatic Clamping Device | ||

| Servo Main Motor | √ ESTUN | Die Clamp | √2V-'T’Quick Change Bottom |

| Hydraulic System | √ REXROTH (Germany ) | Toolings | √Promecam Punch 85° |

| ❏HAWE 5-Point Monitoring Safety Pressure Valve (CE) | √ 2V Die | ||

| Hydraulic Cylinder | √ Zero leakage Hydraulic Cylinder | ❏4V 60mm Die | |

| Magnetic Scale | √ Italy GIVI | ❏Customized Toolings | |

| Linear Guide Rail | √ Diameter not less than 20mm | Back Protector | √ Barrier |

| Ball Screw | √ Diameter not less than 20mm | ❏ Electric Auto Alu Roll-up Door | |

| Oil Pump | √ Le (Brands under REXROTH ) | Safety Light Curtain | ❏DSP-AP+MCS |

| Servo Motor (back gauge) | √ ESTUN | ❏AKAS lc2m+FMSC | |

| High-Pressure Pipeline | √ PARKER | ❏AKAS lc2m+GMSA (Contain speed monitoring) | |

| AC Contactor | √ Schneider | CE | ❏Electrical Setup & CE certificate |

Plegadora CNC a la venta

»Comprobar el parámetro técnico

| Technical Specifications/Model) | M1 60/1500 | M3 110/3100 | M3 170/3100 | M3 220/3100 | M4 110/4100 | M4 170/4100 | M4 220/4100 | M4 320/4100 |

|

|---|---|---|---|---|---|---|---|---|---|

| Nominal Force (KN) | 600 | 1100 | 1700 | 2200 | 1100 | 170 | 2200 | 3200 | |

| Bending Length (mm) | 1500 | 3100 | 3100 | 3100 | 4100 | 4100 | 4100 | 4100 | |

| Side Frame Distance (mm) | 1200 | 2600 | 2600 | 2600 | 3600 | 3600 | 3600 | 3600 | |

| Ram Stroke (mm) | 215 | 200 | 200 | 200 | 200 | 200 | 200 | 300 | |

| Opening Height(mm) | 525 | 575 | 575 | 575 | 575 | 575 | 575 | 680 | |

| Oil volume (L) | 75 | 180 | 180 | 180 | 350 | 350 | 350 | 350 | |

| Throat depth (mm) | 350 | 410 | 410 | 410 | 410 | 410 | 410 | 410 | |

| Ram Speed | Down Speed (mm/s) | 200 | 220 | 180 | 160 | 220 | 180 | 160 | 120 |

| Pressing (mm/s) | 18 | 14(10) | 11 | 9 | 14 | 11 | 9 | 8 | |

| Return Speed (mm/s) | 200 | 150 | 140 | 120 | 150 | 120 | 110 | 100 | |

| Electrical Parameters | Main Motor Power( KW) | 8.7 | 10.8 | 13.2 | 16.7 | 13.2 | 13.2 | 16.7 | 21.3 |

| Working voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | |

| Backgauge Data Sheet Reference | Axis travel(mm) | 500 | 620 | 620 | 620 | 620 | 620 | 620 | 620 |

| X Axis working speed(mm/s) | 400 | 250 | 250 | ±0.10 | 250 | 250 | ±0.10 | 250 | |

| X Axis Accuracy(mm) | ±0.05 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | ±0.10 | |

| R Axis travel(mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| R Axis working speed(mm/s) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| R Axis Accuracy(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| Z Axis travel(mm) | 350 | 1900 | 1900 | 1900 | 2000 | 2000 | 2900 | 2900 | |

| Z Axis working speed(mm/s) | 1200 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | |

| Z Axis Accuracy(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| Y Axis Accuracy(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Y Axis Repeat Accuracy(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Workpiece straightness(mm) | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | ≤±0.3/1000 | |

| Bending angle accuracy (°) | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | ≤±0.5 | |

| Dimension | Length mm | 2300 | 3950 | 3970 | 3970 | 4970 | 4970 | 4970 | 4970 |

| Width mm | 1400 | 1450 | 1550 | 1750 | 1850 | 1550 | 1750 | 1850 | |

| Height mm | 2550 | 2695 | 2695 | 2695 | 2765 | 2695 | 2695 | 2890 | |

| Weight (KG) | ~5000 | ~6900 | ~8200 | ~11800 | ~8200 | ~10400 | ~14800 | ~16000 | |

Plegadora grande

Plegadora hidráulica en tándem

→110 t/3100 mm*2 en tándem

→170 t/3100 mm*2 en tándem

→220 t/3100 mm*2 en tándem

→170 t/4100 mm*2 en tándem

→220 t/4100 mm*2 en tándem

→320 t/4100 mm*2 en tándem

¡Solicite una propuesta técnica ahora!

Preguntas frecuentes

¿Qué modelos están disponibles para sus productos de prensas plegadoras?

«Ofrecemos tres series de productos principales: M, H y E. La serie M tiene la gama más completa, que incluye 60 t/2050 mm, 60 t/2550 mm, 110 t/3100 mm, 110 t/4100 mm, 170 t/3100 mm, 170 t/4100 mm, 220 t/3100 mm, 220 t/4100 mm, 250 t/4100 mm, 320 t/3100 mm, 320 t/4100 mm, 400 t/4100 mm y 500 t/4100 mm. La serie H, por otro lado, incluye 60 t/1500 mm, 60 t/2050 mm, 60 t/2550 mm, 110 t/3100 mm, 170 t/3100 mm, 220 t/3100 mm, 110 t/4100 mm, 170 t/4100 mm y 220 t/4100 mm, ofreciendo una selección más pequeña que la serie M. Esto se debe a que las prensas plegadoras más grandes requieren una cubierta de marco cerrado, lo que aumenta significativamente los costes y la complejidad de la instalación, el transporte y el mantenimiento.

¿Pueden proporcionar una prensa plegadora en tándem?

Sí, podemos. Las de 170 t/3100 mm y 220 t/3100 mm son las prensas plegadoras en tándem que fabricamos con más frecuencia. Tenemos una amplia experiencia en soluciones en tándem. Puede ponerse en contacto con nuestros asesores de ventas para solicitar un vídeo.

¿Puedo personalizar mi propia marca?

El diseño de la serie H se puede personalizar con su elección de colores y logotipo. Después de la cooperación, le proporcionaremos representaciones de productos y vídeos con los colores y el logotipo de su marca, en consonancia con su estrategia de marketing. Si el diseño de la serie H no satisface sus necesidades y requiere un diseño de prensa plegadora completamente nuevo, podemos hacer los arreglos para que un diseñador industrial cree una solución a medida para usted.

¿Cuál es su plazo de entrega?

El plazo de entrega para los modelos estándar es de 45 a 50 días, y para los productos personalizados, es de 60 a 70 días.

Necesito la certificación CE. ¿Pueden proporcionarla?

Sí. Podemos realizar ajustes de seguridad eléctrica para el sistema de acuerdo con los requisitos de la CE y proporcionar el certificado CE.

Soy un usuario final y no estoy seguro de cómo elegir la prensa plegadora adecuada para mis necesidades. ¿Pueden darme recomendaciones?

Si puede describir los materiales que dobla regularmente, incluyendo el tipo de material, el grosor o proporcionar un dibujo de la pieza de trabajo, nuestros ingenieros le ayudarán a seleccionar el modelo adecuado.

¿Ofrecen garantía?

Prometemos una garantía de un año. Durante este período, cualquier problema de calidad con las piezas causado por factores ajenos al error humano puede ser reparado o reemplazado de forma gratuita. Sin embargo, tendrá que cubrir los gastos de envío en ambos sentidos.

¿Cómo ofrecen el servicio postventa?

Después de que ambas partes firmen el contrato de venta, en función de los requisitos específicos del cliente, se podría proporcionar orientación y formación por vídeo a distancia de forma gratuita. El contenido de la formación incluye:

- Principios e introducción de la prensa plegadora CNC.

- Componentes del sistema de la prensa plegadora CNC.

- Funcionamiento de la prensa plegadora CNC.

- Mantenimiento de la prensa plegadora CNC.

- Soluciones para problemas comunes

Si necesita un servicio in situ, deberá proporcionar el billete de avión de ida y vuelta, el alojamiento y una dieta diaria para el ingeniero.

¿Dónde está la dirección de envío?

Nuestras máquinas de prensas plegadoras se envían desde Yangzhou, China. Si ya tiene otros proveedores en China pero desea comprar nuestros accesorios de plegado, podemos enviarlos de forma gratuita a su dirección de envío existente en China.

El coste de envío es demasiado alto. ¿Cómo puedo reducirlo?

Normalmente, un contenedor HC de 40 pies puede contener 2 prensas plegadoras con una longitud de trabajo de 4100 mm o menos. Recomendamos comprar 2 unidades a la vez para compartir el coste de envío.

¿Cómo se transportan las prensas plegadoras grandes?

Las prensas plegadoras de más de 320 t de tonelaje deben desmontarse antes del envío y luego volver a montarse en su fábrica. Tenemos soluciones de envío especializadas en marcha. Generalmente, nuestro equipo de postventa deberá instalar la máquina in situ, con al menos 2 ingenieros. El proceso de instalación suele durar alrededor de un mes, y estos costes se incluirán en el presupuesto que se le proporcione.