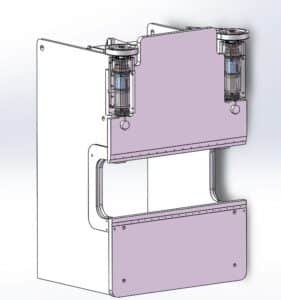

Electric Press Brake

Highlights of Electric Press Brake

High Precision

It uses an electric drive system instead of a traditional hydraulic system, significantly reducing energy consumption. Compared to hydraulic bending machines, the electric version can precisely control energy input, improving operational efficiency and reducing running costs, especially in large-scale production or prolonged use scenarios.

Energy Saving

It is controlled by a servo motor, achieving extremely high positioning accuracy, ensuring consistent bending operations every time. This high-precision control results in more stable product quality and reduces human error, making it particularly suitable for complex tasks requiring high precision.

Safety Guarantee

It does not rely on hydraulic fluids or oils, reducing pollution risks and eliminating issues like oil leaks. With no hydraulic system, the electric bending machine requires less maintenance, minimizing downtime and repair costs, making it more cost-effective over the long term.

Configuration Selection Guide

| Item | Description |

|---|---|

| Axis | 4 |

| 6 | |

| CNC System | Laimore |

| Servo Main Motor | Chinese brand |

| Magnetic Scale | Italy GIVI |

| Ball Screw | Chinese brand |

| Servo Motor (back gauge) | Chinese brand |

| AC Contactor | Schneider |

| Foot Pedal | Double foot pedal |

| Clamp | Standar manule clamp |

| Toolings | 80°/82°/85° Punch |

| 2V (v8 v12)Die | |

| Included | |

| 2× main servo motors with brakes (custom, Tomorrow Intelligent Control) |  |

| 1× large & small reduction pulleys + rack belt (Gates, USA) | |

| 2× braking resistors | |

| 1× pendant arm | |

| 2× rear-stop servo motors (INOVANCE) | |

| 2× electric cylinders (heavy-duty ball screws, Nanjing Technology) | |

| 1× CNC system MT15 (Laimore) |

Technique Specification

| Parameter | 40t/1600mm | 60t/2050 | 80t/2550 |

|---|---|---|---|

| Nominal Force(KN) | 40 | 60 | 80 |

| Reduction Ratio | 5 | 4.28 | 4.28 |

| Lead (mm) | 20 | 20 | 20 |

| Main Motor Power(KW) | 7.5KW | 16.5KW | 23KW |

| Down Speed (mm/s) | 200 | 186.9 | 186.9 |

| Pressing (mm/s) | 50 | 50 | 50 |

| Return Speed (mm/s) | 200 | 186.9 | 186.9 |

| Ram Stroke(mm) | 140 | 140 | 140 |

Electric Press Brake for Sale

Request a Technical Proposal Now!

FAQ

What models are available for your press brake products?

“We offer three main product series: M, H, and E. The M-series has the most comprehensive range, including 60t/2050mm, 60t/2550mm, 110t/3100mm, 110t/4100mm, 170t/3100mm, 170t/4100mm, 220t/3100mm, 220t/4100mm, 250t/4100mm, 320t/3100mm, 320t/4100mm, 400t/4100mm, and 500t/4100mm. The H-series, on the other hand, includes 60t/1500mm, 60t/2050mm, 60t/2550mm, 110t/3100mm, 170t/3100mm, 220t/3100mm, 110t/4100mm, 170t/4100mm, and 220t/4100mm, offering a smaller selection than the M-series. This is because larger press brakes require a closed-frame cover, which significantly increases the costs and complexity of installation, transportation, and maintenance.

Can you provide tandem press brake?

Yes, we can. 170t/3100mm and 220t/3100mm are the tandem press brake we make most often. We have extensive experience in tandem solution. You can contact our sales consultants to request a video.

Can I customize my own brand?

The H-series design can be customized with your choice of colors and logo. After cooperation, we will provide product renderings and videos featuring your brand’s colors and logo, aligning with your marketing strategy. If the H-series design doesn’t meet your needs and you require a completely new press brake design, we can arrange for an industrial designer to create a tailored solution for you.

What is your delivery lead time?

The lead time for standard models is 45-50 days, and for custom products, it is 60-70 days.

I need CE certification. Can you provide it?

Yes. We can make electrical safety settings for the system according to CE requirements and provide the CE certificate.

I am an end user, and I’m not sure how to choose the right press brake for my needs. Can you provide recommendations?

If you can describe the materials you bend regularly, including the material type, thickness, or provide a workpiece drawing, our engineers will assist you in selecting the right model.

Do you offer a warranty?

We promise one-year warranty. During this period, any quality issues with parts caused by factors other than human error can be repaired or replaced free of charge. However, you will need to cover the shipping costs both ways.

How do you provide after-sales service?

After both parties sign the sales contract, based on the specific requirements of the customer, free remote video guidance and training could be provided.The training content includes:

- Principles and introduction of the CNC press brake.

- System components of the CNC press brake.

- Operation of the CNC press brake.

- Maintenance of the CNC press brake.

- Solutions for common issue

If you need a on-site service, you shall provide round-trip airfare, accommodation, and a daily allowance of the engineer.

Where is the shipping address?

Our press brake machines are shipped from Yangzhou, China. If you already have other suppliers in China but wish to purchase our bending accessories, we can ship them for free to your existing shipping address in China.

The shipping cost is too high. How can I reduce it?

Typically, a 40ft HC container can fit 2 press brakes with a 4100mm or smaller working length. We recommend purchasing 2 units at once to share the shipping cost.

How are large press brakes transported?

Press brakes over 320t in tonnage need to be disassembled before shipping and then reassembled at your factory. We have specialized shipping solutions in place. Generally, our after-sales team will be required to install the machine on-site, with at least 2 engineers. The installation process typically takes about one month, and these costs will be included in the quotation provided to you.