China’s press brake industry features ten standout brands for 2025: Yawei, JFY, SENFENG, HARSLE, Krrass, Dumark, SC (Shenchong), YSD, Accurpress, and Meca. These companies lead the market with strong reputations for innovation and reliability. Their machines show advancements in CNC technology, greater automation with artificial intelligence and IoT, and a focus on environmentally sustainable manufacturing. Manufacturers continue to improve product quality and efficiency, making these brands essential for anyone considering a new press brake.

Key Takeaways

- Explore top Chinese press brake brands like Yawei, JFY, and SENFENG for reliable and innovative solutions in 2025.

- Consider the advantages of each brand, such as Yawei’s advanced technology and JFY’s strong after-sales support.

- Evaluate key features like CNC control systems and energy-efficient designs to enhance productivity and reduce costs.

- Assess after-sales service and support networks to ensure quick troubleshooting and access to spare parts.

- Match machine capabilities to your production needs, considering factors like space, power, and budget.

1. Yawei

Advantages

Yawei stands out as a leader among Chinese press brake manufacturers. The company has built a strong reputation for reliability and innovation. Many users choose Yawei for its consistent performance and advanced technology.

- Yawei offers a wide range of sheet metal processing machinery.

- The brand competes strongly in the 80-ton to 160-ton press brake segment.

- Yawei invests in global promotion and has established local distributors in many regions.

- The company provides machines with high-end European components, which ensures quality and durability.

- Yawei integrates robotic systems, making automation easier for manufacturers.

Disadvantages

Yawei press brakes have some drawbacks that buyers should consider.

- The initial cost of Yawei machines can be higher than some competitors.

- Advanced features may require specialized training for operators.

- Some users report longer lead times for delivery due to high demand.

- The complexity of CNC systems may challenge new users who lack experience.

Features

Yawei press brakes include several technological advancements that set them apart. The table below highlights key features and their benefits:

| Feature/Advancement |

Description |

| High Reliability |

Machines deliver consistent results and rarely break down. |

| Hydraulic and Electric Versions |

Users can choose the best configuration for their needs. |

| High-End Components |

European-sourced parts improve performance and lifespan. |

| CNC Hydraulic Crowning |

This feature increases bending precision and simplifies operation. |

| Robotized Systems |

Many Yawei machines work with robots for automated production. |

| Precision WILA Tooling |

Accurate tooling allows quick changes and precise part production. |

| Over-Dimensioned Frames |

Strong frames handle high tonnages and provide stability during use. |

Yawei continues to lead the market with reliable, innovative, and high-quality press brake solutions. The company’s focus on technology and global reach makes it a top choice for manufacturers in 2025.

2. JFY

Advantages

JFY has earned recognition as a top press brake manufacturer in China. The company belongs to the TRUMPF Group, which gives it access to advanced European technology.

- JFY offers a broad product range, including CNC press brakes and fiber laser cutting machines.

- The brand provides reliable machines with stable performance.

- JFY invests in research and development, which leads to frequent product upgrades.

- Many users appreciate the user-friendly interface and easy programming.

- JFY maintains a strong after-sales support network in China and abroad.

Tip: JFY’s connection with TRUMPF often means better access to spare parts and technical expertise.

Disadvantages

JFY press brakes present some challenges for buyers.

- The machines sometimes cost more than other domestic brands.

- Some users report that technical documentation is not always available in multiple languages.

- JFY’s focus on high-tech solutions may require operators to have advanced training.

- The company’s global presence is growing, but service coverage in some regions remains limited.

Features

JFY press brakes include several notable features that help manufacturers improve productivity. The table below summarizes key features and their benefits:

| Feature |

Benefit |

| TRUMPF Technology |

Ensures high precision and reliability |

| CNC Control Systems |

Simplifies operation and increases accuracy |

| Energy-Saving Design |

Reduces power consumption and lowers operating costs |

| Modular Construction |

Allows easy upgrades and maintenance |

| Automatic Tool Changer |

Speeds up production and reduces downtime |

| Remote Diagnostics |

Enables quick troubleshooting and support |

JFY continues to push the boundaries of press brake technology. The company’s commitment to innovation and quality makes it a strong contender for manufacturers seeking advanced solutions in 2025.

3. SENFENG

Advantages

SENFENG has become a well-known name in the Chinese press brake market. The company focuses on integrating smart technology into its machines.

- SENFENG offers a wide selection of press brakes for different production needs.

- The brand uses advanced CNC systems that improve accuracy and speed.

- Many users praise the intuitive touch-screen controls.

- SENFENG provides strong technical support and training for operators.

- The company invests in research to develop energy-efficient machines.

Note: SENFENG’s commitment to smart manufacturing helps factories reduce labor costs and increase productivity.

Disadvantages

SENFENG press brakes have some limitations that buyers should consider.

- The machines may require frequent software updates to maintain peak performance.

- Some users report that spare parts can take longer to arrive in certain regions.

- The initial setup process can be complex for new users.

- SENFENG’s global service network is still expanding, which may affect support in remote areas.

Features

SENFENG equips its press brakes with several modern features. The table below highlights the most important ones:

| Feature |

Description |

| Smart CNC Controller |

Enhances precision and simplifies programming |

| Touch-Screen Interface |

Allows easy operation and quick adjustments |

| Energy-Saving Design |

Reduces electricity usage and lowers operating costs |

| Automatic Back Gauge |

Improves repeatability and speeds up production |

| Remote Monitoring |

Lets users track machine status from anywhere |

| Modular Construction |

Makes maintenance and upgrades easier |

SENFENG continues to push for innovation in the press brake industry. The company’s focus on smart technology and user-friendly design makes its machines a strong choice for manufacturers in 2025.

4. HARSLE

Advantages

HARSLE has built a strong reputation in the Chinese press brake market. Many manufacturers choose HARSLE for its reliable machines and customer-focused approach. The company stands out for its commitment to after-sales service. Customers often mention the support they receive during the entire machine lifecycle. For example, a Russian client described the assistance as comprehensive, from the first inquiry to the machine’s full operation. HARSLE’s hands-on approach helps users solve problems quickly and efficiently.

- HARSLE provides strong after-sales service.

- The company offers support from the initial inquiry to machine installation.

- Many users report satisfaction with technical guidance and troubleshooting.

- HARSLE’s team responds quickly to customer questions.

HARSLE also invests in research and development. The company introduces new features that improve productivity and safety. Many users appreciate the user-friendly controls and clear instructions.

Disadvantages

HARSLE press brakes have some drawbacks that buyers should consider. Some users report that the machines require regular maintenance to keep them running smoothly. Spare parts may take longer to arrive in certain regions. The company continues to expand its global service network, but coverage remains limited in some remote areas. Operators sometimes need extra training to use advanced features.

Note: Buyers should plan for possible delays in spare parts delivery, especially outside major markets.

Features

HARSLE equips its press brakes with several advanced features. The table below highlights the most important ones:

| Feature |

Description |

| CNC Control System |

Simplifies programming and increases accuracy |

| Hydraulic Crowning |

Improves bending precision and reduces errors |

| Safety Light Curtains |

Protects operators during machine operation |

| Quick-Change Tooling |

Reduces setup time and increases productivity |

| Energy-Efficient Design |

Lowers power consumption and operating costs |

| Remote Diagnostics |

Allows fast troubleshooting and technical support |

HARSLE continues to improve its machines with new technology and user-friendly designs. The company’s focus on customer support and innovation makes it a strong choice for manufacturers in 2025.

5. Krrass

Advantages

Krrass has established a strong presence in the Chinese press brake market. The company focuses on delivering machines that balance cost and performance. Many manufacturers choose Krrass for its competitive pricing and reliable quality. Krrass invests in modern production lines and uses advanced testing equipment. This approach helps ensure consistent machine performance.

- Krrass offers a wide range of press brakes for different applications.

- The company provides flexible customization options for clients.

- Krrass machines feature user-friendly controls that simplify operation.

- The brand maintains a good reputation for timely delivery.

- Many users report positive experiences with technical support.

Tip: Krrass often provides online training resources, which help new operators learn quickly.

Disadvantages

Krrass press brakes have some limitations. Some users note that the machines may not include the latest high-end features found in premium brands. Krrass focuses on affordability, which can mean fewer advanced automation options. The company’s global service network continues to grow, but support in some regions remains limited. Some buyers mention that documentation may lack detail for complex tasks.

- Advanced CNC features may require additional upgrades.

- Spare parts availability can vary by location.

- Some users need extra training for specialized operations.

Features

Krrass equips its press brakes with practical features that meet most manufacturing needs. The table below highlights key features and their benefits:

| Feature |

Benefit |

| CNC Controller |

Improves accuracy and reduces setup time |

| Hydraulic System |

Ensures stable and consistent bending force |

| Quick-Change Tooling |

Speeds up tool changes and increases efficiency |

| Safety Devices |

Protects operators during machine use |

| Modular Design |

Allows easy maintenance and future upgrades |

Krrass continues to attract manufacturers who want reliable press brake solutions at a reasonable price. The company’s focus on value and customer support makes it a brand to watch in 2025.

6. Dumark

Advantages

Dumark has gained attention in the Chinese press brake market for its focus on cost-effective solutions and practical machine designs. Many manufacturers choose Dumark for its straightforward approach to bending technology. The company offers reliable machines that perform well in daily production. Dumark’s press brakes often feature simple controls, which help operators learn quickly. The brand provides flexible options for small and medium-sized workshops. Customers appreciate Dumark’s responsive technical support and willingness to customize machines for unique needs.

- Dumark machines offer good value for money.

- The company responds quickly to customer questions.

- Operators find the controls easy to understand.

- Dumark supports customization for special projects.

Dumark’s machines suit businesses that want dependable performance without unnecessary complexity.

Disadvantages

Dumark press brakes have some limitations. The machines may not include the latest high-end automation features found in premium brands. Some users report that Dumark’s global service network remains limited, which can affect support in remote regions. The company focuses on essential functions, so advanced CNC options may require upgrades. Spare parts availability sometimes varies by location. Operators may need extra training for specialized bending tasks.

- Fewer advanced automation features compared to top-tier brands.

- Limited international service coverage.

- Some upgrades may be necessary for complex operations.

Features

Dumark equips its press brakes with practical features that meet most workshop needs. The company’s popular models include the 100T*2500 CNC Hydraulic Bending Machine, which offers reliable performance for a range of applications.

Popular Dumark Press Brake Models:

The table below highlights key features and their benefits:

| Feature |

Benefit |

| CNC Hydraulic System |

Provides stable and accurate bending |

| Simple Control Panel |

Makes operation easy for new users |

| Customizable Options |

Supports unique production requirements |

| Sturdy Frame Design |

Ensures long-term durability |

| Safety Protection |

Helps keep operators safe during use |

Dumark continues to serve manufacturers who value simplicity, reliability, and affordability in their press brake equipment.

7. SC (Shenchong)

Advantages

SC (Shenchong) has built a strong reputation in the Chinese press brake industry. The company stands out for its commitment to innovation and quality. Shenchong offers cost-effective machines that deliver high performance. Many manufacturers choose Shenchong because their press brakes provide similar or better capabilities than European or North American models, but at a lower price. This allows businesses to invest savings in other areas. Shenchong integrates advanced automation, including robotic bending cells and automated handling systems. These features help factories increase productivity and reduce labor needs. The company’s self-developed servo hybrid CNC press brake offers low noise, stability, and reduced oil consumption. Shenchong’s focus on energy efficiency and high precision makes their machines ideal for heavy industry and high-volume manufacturing.

Shenchong’s automation department supports specialized customer needs in cutting, bending, and forming.

Disadvantages

Shenchong press brakes have some limitations. Some users report that the initial setup of automated systems can be complex. Operators may need extra training to use advanced features. The company’s large-tonnage machines require significant space and infrastructure, which may not suit smaller workshops. Shenchong’s global service network continues to expand, but support in remote regions can be limited. Spare parts for specialized models may take longer to arrive.

- Complex automation setup may challenge new users.

- Large machines need more space and resources.

- Service coverage in some areas remains limited.

- Delivery times for unique parts can vary.

Features

Shenchong’s history shows a steady progression in technology and product development:

- In 2006, Shenchong researched and designed the tandem press brake 2WE67K-1000T/6500 and a large shear 16X10000.

- In 2007, they produced a shipbuilding rolling machine 25X13000 and a shear 50X2500.

- In 2008, they researched and designed a 9 axes CNC press brake machine.

- In 2010, they designed and made an anti-twist hydraulic shearing machine.

- In 2012, they researched and designed a high-speed 4 axes CNC press brake.

- In 2014, they designed and produced a simple CNC hydraulic press brake, establishing a solid foundation for long-term growth.

The table below highlights key features of Shenchong press brakes:

| Feature |

Description |

| Servo Hybrid CNC System |

Delivers low noise, stability, and energy savings |

| Robotic Bending Cells |

Automates production for high-volume tasks |

| High Precision |

Ensures consistent and accurate bending results |

| Energy-Efficient Design |

Reduces oil consumption and operating costs |

| Large-Tonnage Capability |

Supports heavy industry and large-scale manufacturing |

| Automation Department |

Customizes solutions for cutting, bending, and forming |

Shenchong continues to lead with innovative, high-performance press brake solutions that meet the demands of modern manufacturing.

8. YSD

Advantages

YSD holds a respected position in the Chinese press brake industry. The company has built a reputation for delivering reliable machines at a competitive price. Many customers praise the quality of YSD press brakes and the professionalism of the engineering team. Users often mention that the machines arrive with all necessary tools, which helps them start production quickly. YSD engineers respond to technical questions with expertise and patience. The machines perform well in daily operations and offer strong value for the investment.

- Customers describe the press brake as excellent quality.

- The machine includes all required tools for immediate use.

- YSDCNC engineers show professionalism when answering questions.

- Users highlight strong performance and good value for the price.

YSD continues to attract manufacturers who want dependable equipment and responsive support.

Disadvantages

YSD press brakes have some limitations. Some users report that the machines may not include the most advanced automation features found in premium brands. The company focuses on essential functions, which can mean fewer options for high-end customization. YSD’s global service network is still growing, so support in remote regions may be limited. Operators sometimes need extra training to use all features efficiently. Spare parts for specialized models may take longer to arrive.

Note: Buyers should consider their need for advanced automation and check local service availability before purchasing.

Features

YSD equips its press brakes with a range of features that support efficient and safe operation. The machines offer a user-friendly interface, which allows operators to set up jobs quickly and store multiple programs for future use. The dual V-clamping system prevents material slippage and ensures precise alignment. YSD uses a high-efficiency hydraulic system that delivers consistent force, even when bending thick metals. The machines achieve high precision, meeting strict tolerances in industries such as automotive and aerospace. Operators can choose from a variety of punch and die sets for different bend profiles. Safety remains a priority, with light curtains, emergency stops, and two-hand operation included. The sealed hydraulic components reduce maintenance needs, and the variable-speed pump lowers energy consumption during idle times. An ergonomic design improves operator comfort and visibility.

| Feature |

Description |

| User-friendly interface |

Quick setup and programming, stores multiple job programs for fast recall and reuse. |

| Clamping mechanism |

Dual V-clamping system prevents slippage and deformation, ensuring material alignment. |

| Hydraulic system |

High-efficiency hydraulic system delivers consistent force for bending thick metals. |

| High precision |

Achieves bending accuracy down to 0.01mm, meeting strict tolerances in various sectors. |

| Tooling options |

Supports a wide range of interchangeable punch and die sets for versatility in bend profiles. |

| Safety features |

Includes light curtains, emergency stop, and two-hand operation for operator protection. |

| Low maintenance |

Sealed hydraulic components extend service intervals. |

| Energy efficiency |

Variable-speed pump reduces power consumption during idle cycles. |

| Ergonomic design |

Intuitive layout and clear visibility improve operator comfort. |

YSD continues to deliver press brake solutions that balance quality, safety, and ease of use for manufacturers in 2025.

9. Accurpress

Advantages

Accurpress has earned a strong reputation in the Chinese press brake market. The company focuses on delivering machines that combine durability with advanced technology. Many manufacturers choose Accurpress for its consistent performance and robust construction.

- Accurpress machines feature heavy-duty frames that handle demanding workloads.

- The brand offers a wide range of models for different production needs.

- Accurpress invests in research to improve bending accuracy and efficiency.

- Many users appreciate the straightforward controls and clear interface.

- The company provides reliable technical support and training resources.

Tip: Accurpress machines often last for many years, making them a solid investment for growing businesses.

Disadvantages

Accurpress press brakes have some drawbacks that buyers should consider.

- The machines can be heavier and larger than similar models, which may require more floor space.

- Some users report that advanced automation features are limited on entry-level models.

- The initial purchase price may be higher compared to basic brands.

- Spare parts for older models sometimes take longer to arrive.

- Operators may need extra training to use all CNC functions effectively.

Features

Accurpress equips its press brakes with several features that help manufacturers achieve precise results. The table below highlights key features and their benefits:

| Feature |

Benefit |

| Heavy-Duty Frame |

Provides stability and reduces vibration |

| CNC Control System |

Increases bending accuracy and simplifies operation |

| Quick-Change Tooling |

Speeds up setup and reduces downtime |

| Safety Light Curtains |

Protects operators during machine use |

| Energy-Efficient Design |

Lowers power consumption and operating costs |

| Modular Construction |

Allows easy maintenance and future upgrades |

Accurpress continues to support manufacturers who need reliable, high-performance press brake solutions. The company’s focus on durability and user-friendly design makes it a top choice for many workshops in 2025.

10. Meca

Advantages

The Meca press brake team is composed of experienced professionals with over 10 years of R&D experience. The team designs the press brakes in-house and commissions trusted factories for production. These press brake models range from 60 tons to 600 tons, catering to the diverse needs of different customers. The team adheres to high standards in every step of the production process, from selecting core components to equipment machining and assembly. By ensuring transparent production processes, they maintain control over the delivery process, ensuring that the products delivered are of exceptionally high quality and stability.

On the other hand, Meca has also demonstrated innovative thinking by actively developing peripheral products for press brakes, including hydraulic fixtures, CNC-following material support devices, and bending angle gauges. These creative products provide a well-rounded complement to the overall press brake solution.

Disadvantages

However, despite the Meca team’s extensive experience in press brake manufacturing, Meca remains an emerging brand with a relatively low market share, as its members have previously worked for other companies.

Features

| Feature |

Benefit |

| Estun Servo Main Motor |

Energy Saving |

| DA, CT, and ESA CNC systems are available as options. |

catering to the preferences and standards of different countries. |

| Bidirectional mechanical deflection compensation system |

More precise than unidirectional compensation. |

| Verified supply chain and reliable components |

Enhance the overall performance of the press |

| A variety of models ranging from 60T to 600T are available |

Designed to meet various application scenarios |

| Modular configuration |

Covering both economical and high-end models |

Meca continues to deliver reliable, high-performance press brake solutions for manufacturers seeking durability and advanced technology in 2025.

Press Brake Quality Evaluation

Choosing the right press brake involves careful evaluation of several factors. Manufacturers should focus on machine structure, technology, and after-sales service to ensure long-term productivity and safety.

Structure & Build

A press brake’s structure and build quality directly affect its reliability and performance. Buyers should look for machines that minimize downtime and reduce maintenance costs. Key factors to assess include:

- Reliability: Machines that operate consistently help maintain production schedules.

- Durability: Strong frames and components extend the lifespan of the press brake.

- Features: Tonnage, bending length, and backgauge systems determine operational efficiency.

- Future Upgrades: Scalable designs allow integration with automation systems.

- Safety Systems: Built-in safety features protect operators and meet regulatory standards.

A well-built press brake supports heavy workloads and adapts to changing manufacturing needs.

Technology

Modern press brake technology improves accuracy and efficiency. CNC control systems simplify programming and enable precise bending. Touch-screen interfaces make operation easier for new users. Energy-saving designs help lower operating costs. Advanced models may include automatic tool changers and remote diagnostics. Manufacturers should consider machines that offer modular construction for easy upgrades. Technology plays a vital role in achieving consistent results and reducing errors.

| Technology Feature |

Benefit |

| CNC Control System |

High bending precision |

| Touch-Screen Interface |

Simple operation |

| Automatic Tool Changer |

Faster production |

| Remote Diagnostics |

Quick troubleshooting |

After-Sales Service

After-sales service ensures that press brake owners receive support throughout the machine’s life. Reliable brands provide technical guidance, training, and fast troubleshooting. Access to spare parts and responsive customer service reduces downtime. Manufacturers should choose suppliers with strong service networks and clear communication. Good after-sales support helps operators solve problems quickly and keeps production running smoothly.

Tip: Evaluate the supplier’s warranty terms and service coverage before purchasing a press brake.

A thorough evaluation of structure, technology, and service helps buyers select a press brake that matches their production goals.

Manufacturers often select press brake brands based on pricing, machine precision, after-sales support, and reputation. Each brand in this list offers unique strengths, from advanced automation to reliable customer service. Buyers should match machine capabilities to production needs and review space, power, and cost requirements. The table below highlights key evaluation criteria:

| Criteria |

Description |

| Space Requirements |

Ensures the machine fits in the shop and allows safe operation. |

| Power Requirements |

Understanding electrical needs is crucial for installation. |

| Cost Considerations |

Evaluating upfront costs and long-term ROI supports sound decisions. |

| Vendor Reputation |

Reliable vendors provide support and training for smooth operation. |

| Support and Maintenance |

Ongoing support and spare parts minimize downtime and boost productivity. |

FAQ

What is a press brake used for?

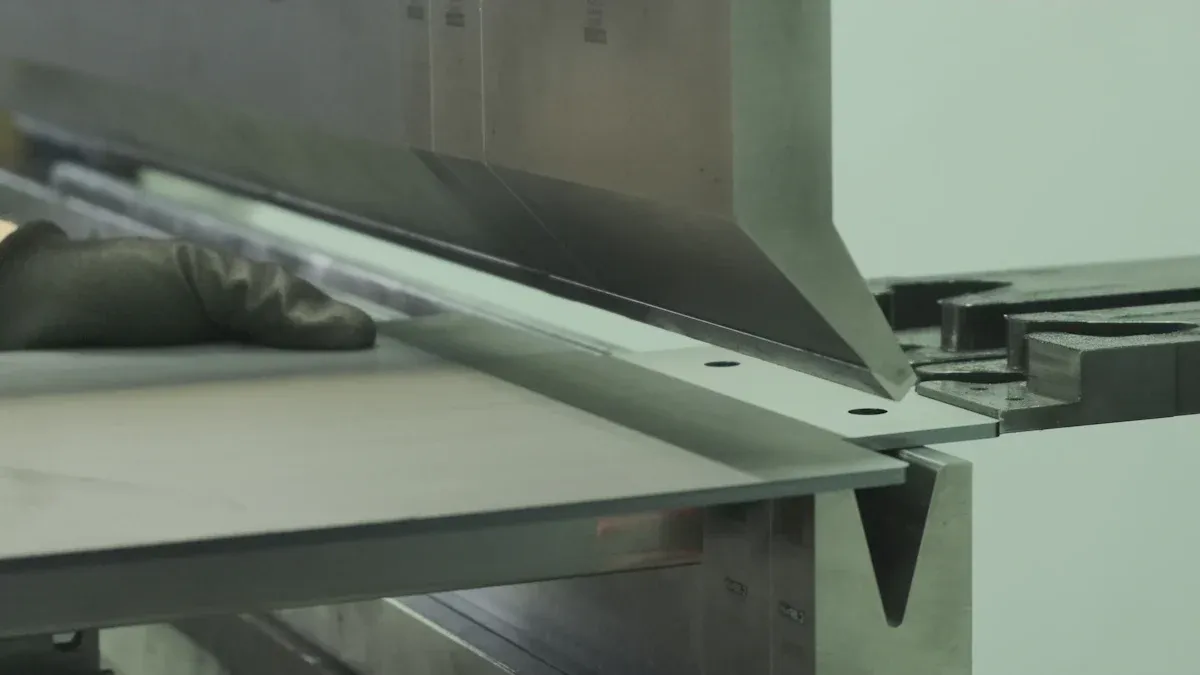

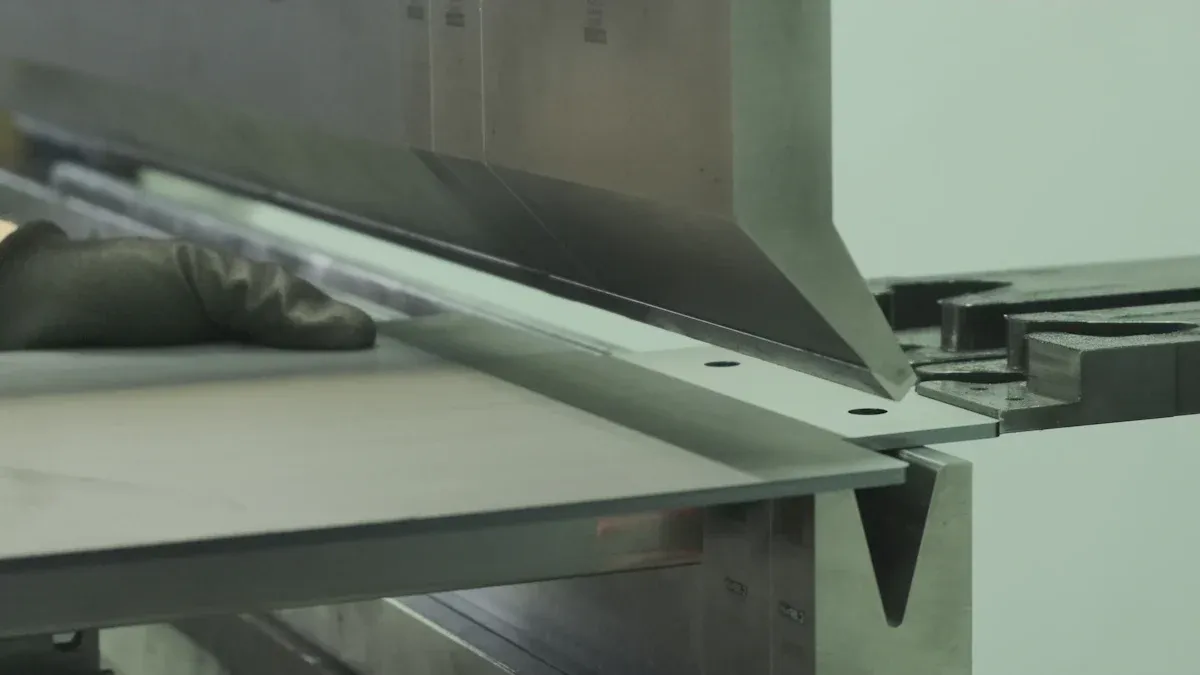

A press brake bends sheet metal into different shapes. Manufacturers use it to make parts for cars, appliances, and machines. The machine uses a punch and die to create precise bends.

How do Chinese press brake brands compare to European brands?

Chinese brands offer strong value and reliable performance. Many use advanced technology and quality components. European brands often cost more but may provide extra features or longer service networks.

What should buyers check before choosing a press brake?

Buyers should check machine size, tonnage, control system, and safety features. They should also review after-sales support and spare parts availability.

Do these brands offer training for operators?

Most leading brands provide training. They offer manuals, videos, and sometimes on-site instruction. This helps operators use the press brake safely and efficiently.