Why Pipe Cleaning is Essential in the Press Brake Machine Manufacturing Process?

Table of Content

This post is also available in:

Español (Spanish) العربية (Arabic) Русский (Russian)

What influence the Press Brake Machine Performance: The Piping Cleanliness

Pipe cleanliness plays a vital role in ensuring stable operation and longer service life for press brake machines. Dirt, debris, and contaminants often build up inside pipes, leading to reduced hydraulic efficiency and compromised machine performance. Regular cleaning of hydraulic circuits and cooling systems helps prevent blockages and costly failures. Many experts recommend including press brake trouble shooting in routine maintenance to catch issues early and maintain optimal reliability.

Key Takeaways

- Clean pipes enhance hydraulic efficiency, leading to smoother operation and fewer interruptions.

- Regular cleaning of hydraulic circuits and coolant systems prevents costly blockages and repairs.

- Maintaining hydraulic oil cleanliness at 5 microns or better protects sensitive components and ensures optimal performance.

- Routine inspections help identify leaks and blockages early, extending the lifespan of press brake machines.

- Implementing preventive measures reduces contamination risks and supports consistent product quality.

Pipe Cleanliness and Press Brake Machine Performance

Clean pipes play a crucial role in the operation of every press brake. When pipes remain free of contaminants, the hydraulic system works efficiently, the machine maintains accuracy, and operators experience fewer interruptions. Regular cleaning of coolant tanks and pipes helps prevent the buildup of harmful materials. Many manufacturers recommend maintaining hydraulic oil cleanliness at a level of 5 microns or better to protect sensitive components and ensure optimal press brake performance.

Hydraulic Efficiency

Hydraulic efficiency depends on the purity of the fluid and the cleanliness of the pipes. Contaminants in the hydraulic system can reduce the effectiveness of the press brake and lead to costly repairs. The most common contaminants found in press brake hydraulic pipes include:

- Particle contamination: Dust and metal shavings cause abrasion and wear.

- Water contamination: Free water leads to rust and corrosion, while dissolved water reduces lubrication.

- Air contamination: Entrained air causes erratic movement and cavitation damage.

- Chemical contamination: Oxidation products harm components and reduce fluid effectiveness.

These contaminants can cause several problems:

- Reduced efficiency due to increased friction and resistance.

- Accelerated component wear, resulting in premature failure.

- Clogging and blockages that disrupt fluid flow.

- Increased heat, which degrades both fluid and machine parts.

- System failures that may require extensive repairs.

Maintaining hydraulic oil cleanliness is essential. The table below shows recommended filtration levels for different applications:

| Filtration Level | ISO Cleanliness Code | Application Type |

|---|---|---|

| 20 microns | 20/18/15 | Low-pressure gear or vane pumps and motor actuators |

| 3 microns | 16/14/11 | Proportional or servo valves, even in low-pressure |

Press brake operators should monitor oil cleanliness and replace filters regularly. Clean hydraulic oil helps the press brake deliver consistent force and smooth movement.

Machine Accuracy

Accurate bending and forming depend on the stability of the hydraulic system. Dirty pipes can introduce unpredictable variables into the press brake process. When contaminants block valves or restrict fluid flow, the machine may produce uneven bends or fail to maintain precise angles. Metal particles and water can damage seals and cylinders, leading to leaks and loss of pressure. Operators notice a decline in product quality when the press brake cannot maintain its programmed settings.

Routine cleaning of coolant tanks and pipes removes manufacturing residue, dust, and debris. New systems often contain leftover particles from assembly. Over time, wear and tear generate additional contaminants. By keeping pipes clean, operators ensure that the press brake maintains its accuracy and delivers reliable results.

Stable Operation

Stable operation is vital for any press brake machine. Clean pipes help prevent unexpected shutdowns and reduce the risk of catastrophic failures. External dust and debris can enter through seals and vents, while moisture may seep in through leaks or contaminated fluid. Thermal stress and oxidation produce harmful by-products that accumulate in the system.

Operators who follow a regular cleaning schedule experience fewer breakdowns and less downtime. They inspect pipes, replace worn seals, and monitor fluid quality. These steps help the press brake run smoothly and extend its service life. A clean hydraulic circuit supports stable operation, allowing the press brake to perform at its best day after day.

Tip: Regular inspection and cleaning of pipes, hydraulic circuits, and coolant tanks can prevent most common issues in press brake systems. Operators should use recommended tools and filtration methods to keep contaminants below the 5-micron threshold.

Press Brake Machine Trouble Shooting: Dirty Pipe Issues

Contamination Effects

Contamination in pipes creates serious problems for press brake machines. Technicians often find that dirt, water, and other foreign particles enter the hydraulic fluid system. These contaminants increase wear on vital components and reduce overall efficiency. Hydraulic fluid contamination stands out as a critical issue in press brake trouble shooting. Operators notice that dirty hydraulic oil causes the machine to lose power and respond slowly. Moisture in the system leads to rust and corrosion, which damages seals and cylinders. When press brake trouble shooting reveals contamination, the team must act quickly to prevent further damage.

Note: Hydraulic systems require consistent monitoring. Contaminants like dirt or moisture can degrade hydraulic oil, reducing system efficiency and causing performance issues.

Many press brake trouble shooting sessions uncover leaks in the hydraulic system. These leaks allow more contaminants to enter, making the problem worse. Dirty fluid also affects the precision of sheet metal bending. The machine may struggle to maintain accurate angles or produce uneven bends. Regular inspection and cleaning help reduce these risks and keep the press brake running smoothly.

Blockages and Downtime

Blockages in pipes lead to unexpected downtime and costly repairs. During press brake trouble shooting, technicians often find that accumulated debris restricts fluid flow. This restriction causes the machine to operate erratically or stop working altogether. Hydraulic fluid contamination, often caused by dirt or water, remains a common reason for system failure. Operators must address these blockages quickly to avoid extended downtime.

- Hydraulic fluid contamination is a critical issue in hydraulic press brakes.

- Contamination is often caused by dirt, water, or other foreign particles entering the fluid system.

- This leads to increased wear on components, reduced efficiency, and potential system failure.

Press brake trouble shooting helps identify the source of blockages. Teams use specialized tools to clear pipes and restore normal operation. They also replace filters and check for leaks to prevent future problems. Consistent press brake trouble shooting and maintenance routines minimize downtime and protect the investment in equipment.

Extending Press Brake Machine Lifespan

Component Wear

Clean pipes play a direct role in reducing wear on press brake components. When hydraulic fluid stays free from dirt and debris, pumps and valves operate smoothly. Contaminants in the system can cause abrasive damage, leading to early failure of critical parts. Operators who focus on pipe cleanliness help extend the lifespan of their machines.

Contaminated hydraulic fluid is one of the leading causes of equipment failure. Maintaining fluid cleanliness is crucial for the longevity of your equipment.

Hydraulic systems with clean pipes show less varnish buildup. Varnish can form quickly in dirty systems, but new fluids and regular cleaning prevent this problem.

Laboratory testing demonstrates that many widely used fluids show varnish formation within 500 hours of operation, while new additive technology solutions show no evidence of varnish formation even after 1,000 hours of use.

By keeping pipes clean, operators protect press brake components from unnecessary stress. This practice helps maintain the average lifespan of a press brake and reduces the risk of sudden breakdowns. Using high-quality fluids and regular maintenance can extend the lifespan of hydraulic pumps and valves.

Using high-quality hydraulic fluids and maintaining cleanliness can significantly extend the lifespan of hydraulic pumps and valves.

Maintenance Frequency

Routine maintenance keeps press brake lifespan at its maximum. Operators should follow a set schedule for cleaning and inspection. Regular attention to pipes and fittings prevents small issues from becoming major failures. The table below outlines recommended intervals for key maintenance tasks:

| Maintenance Task | Recommended Interval |

|---|---|

| Clean hydraulic pipes and components | At least once a month |

| Visually inspect fittings | Monthly |

| Check hydraulic circuit connections | After first 160 hours |

Frequent checks help identify leaks or blockages before they damage press brake components. Consistent cleaning routines support the average lifespan of a press brake and reduce the need for emergency repairs. Operators who follow these guidelines can extend the lifespan of their equipment and ensure reliable performance.

Best Practices for Press Brake Machine Care

Routine Cleaning

Routine cleaning forms the foundation of effective maintenance for press brake machines. Operators use specific tooling to remove debris from hydraulic and cooling system pipes. The most effective cleaning tools include scrapers and chisels made from soft metals like brass, nylon fiber brushes, industrial vacuums, metal-safe cleaning solvents, lint-free cloths, and ultrasonic cleaners. Safety gear such as gloves, goggles, and respirators protects workers during cleaning.

| Method | Description | Suitable For | Precautions |

|---|---|---|---|

| Chemical Cleaning | Apply metal-safe solvents or degreasers. | Grease, fine residues, specific metal types. | Follow manufacturer’s guidelines and safety precautions. Ensure adequate ventilation. Wear appropriate PPE. |

Operators clean pipes and coolant tanks regularly to maintain the design and manufacturing quality of the press brake. Routine cleaning prevents contamination and supports the tooling system, which relies on clean hydraulic circuits for consistent performance.

Inspection Procedures

Inspection procedures play a key role in regular maintenance management. Technicians inspect the tooling system daily to catch minor issues before they become major failures. They monitor the hydraulic system for leaks and blockages, ensuring efficient operation. Regular calibration maintains precision and alignment, which improves the quality of finished products.

- Regular maintenance extends the lifespan of press brake machines.

- It reduces the risk of costly repairs and unexpected downtime.

- Consistent bending accuracy depends on thorough inspection.

- Workplace safety improves when operational standards are maintained.

Technicians use specialized tooling to inspect pipes and fittings. They check seals and breathers, ensuring the design and manufacturing quality of the machine remains high. Inspection supports the overall maintenance strategy and helps operators avoid emergency repairs.

Preventive Measures

Preventive measures help operators avoid pipe contamination and extend the life of the tooling system. They maintain cleanliness at entry areas to prevent contaminants from reaching hydraulic lines. Maintenance schedules include checking seals and breathers, cleaning tools between uses, and handling fluids properly. Operators use filter-transfer pumps instead of open containers to minimize exposure to contaminants. Quick couplers receive regular cleaning before connections.

- High-quality hydraulic fluids meet system specifications.

- Proper filtration systems catch impurities before they cause damage.

- Regular inspection and replacement of seals and breathers prevent leaks.

A major automotive stamping facility reduced unplanned downtime by 60% after implementing quarterly oil analysis and fixing a faulty breather cap. Proactive maintenance and preventive measures lower repair costs and improve productivity. Investing in maintenance is more cost-effective than replacing parts or machines. Operators who follow these best practices maintain the tooling system and ensure consistent quality.

Tip: Preventative maintenance reduces the likelihood of production line downtime and supports long-term machine reliability. 🛠️

Clean pipes support stable and long-lasting press brake performance. Operators who follow regular cleaning routines help machines run efficiently and avoid costly repairs.

- Pipe cleanliness reduces wear on components.

- Routine maintenance extends machine lifespan.

- Best practices lower the risk of downtime.

Regular care keeps press brakes reliable and productive. Operators should make pipe inspection and cleaning a top priority.

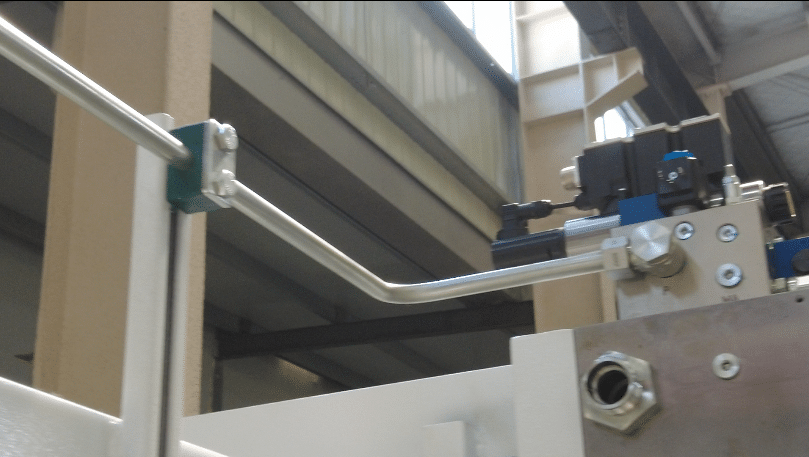

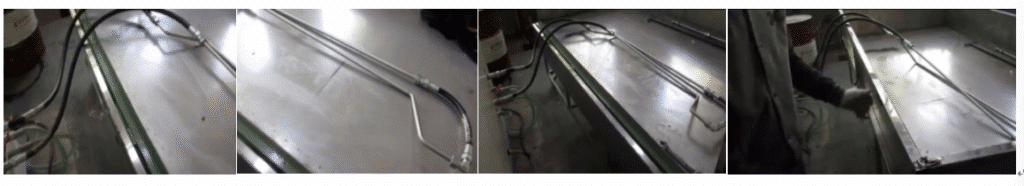

Piping Cleanliness Process of Meca Press Brake Machine

At Meca, we take the following steps to ensure the highest cleanliness standards for the press brake machine’s piping system:

- After cutting, we use an air gun to blow out iron shavings from the interior of the steel pipes.

- We clean the pre-assembled fittings by brushing off any detached zinc layers.

FAQ

How often should operators clean press brake machine pipes?

Operators should clean press brake pipes at least once a month. Regular cleaning prevents contamination and supports stable machine performance. Many manufacturers recommend monthly cleaning to maintain hydraulic efficiency and extend equipment lifespan.

What signs indicate dirty pipes in a press brake machine?

Common signs include slow machine response, uneven bends, leaks, and increased noise. Technicians may notice reduced hydraulic pressure or frequent system errors. These symptoms suggest contamination or blockages in the pipes.

Which tools work best for cleaning hydraulic pipes?

Operators use brass scrapers, nylon brushes, industrial vacuums, and lint-free cloths. Ultrasonic cleaners help remove fine particles. Safety gear such as gloves and goggles protects workers during cleaning.

Can dirty pipes affect product quality?

Dirty pipes can cause uneven bends and inaccurate angles. Contaminants block valves and restrict fluid flow. The press brake may fail to maintain programmed settings, leading to lower product quality.

What preventive measures reduce pipe contamination?

Operators use filter-transfer pumps, clean seals, and high-quality fluids. Regular inspection and cleaning routines help prevent contamination. Many facilities also perform quarterly oil analysis to catch issues early.