- Raw Material -Made of 42CrMo material.

- High Precision -The cutting edge is processed using European grinding techniques in a single operation, ensuring uniform angle, R-angle, and height for the same model of the die. The key dimensional accuracy is maintained within ±0.02mm, guaranteeing consistent assembly precision regardless of purchase time.

- Standardization- Compatible with leading international brands, allowing interchangeable assembly. Segmented dies enable flexible bending of any length, and standardized manufacturing eliminates secondary corrections

- Enhanced Durability- Undergoes full quenching and fine grinding for superior longevity. Die hardness is rated at HRC49±2.

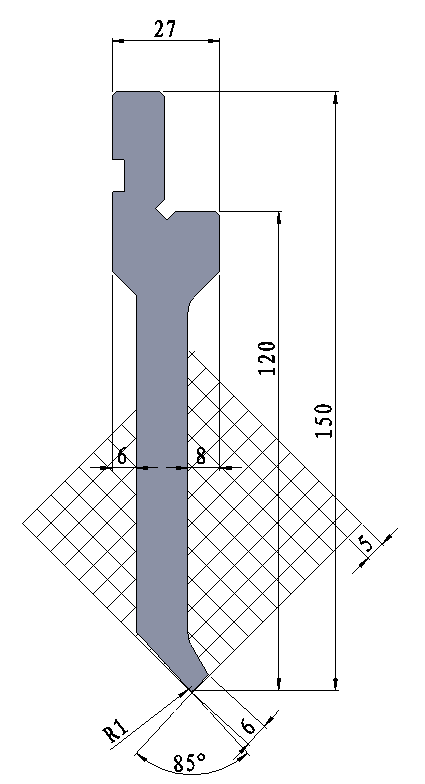

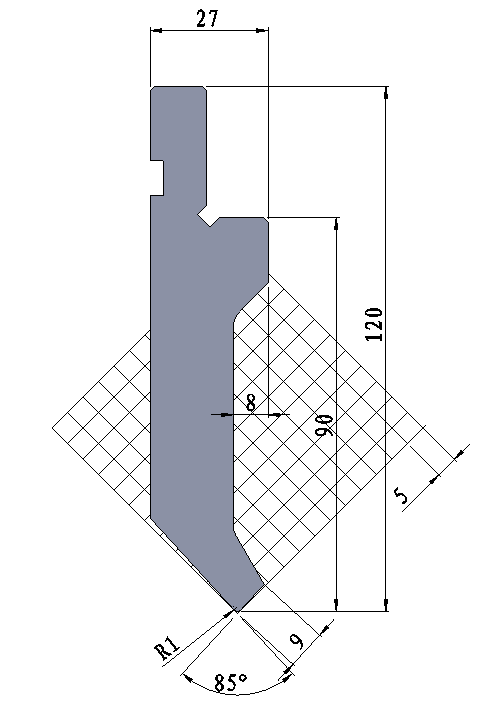

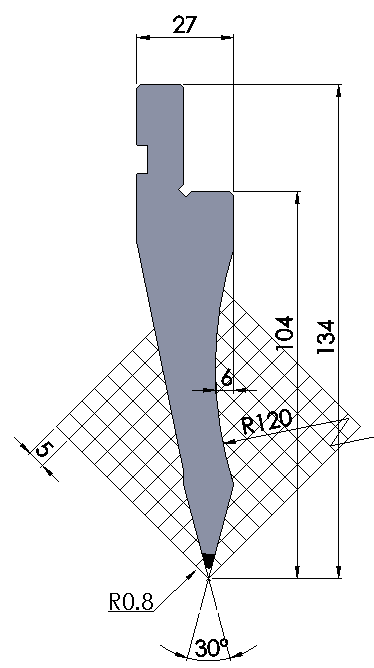

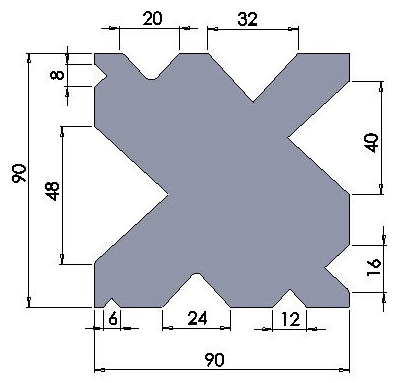

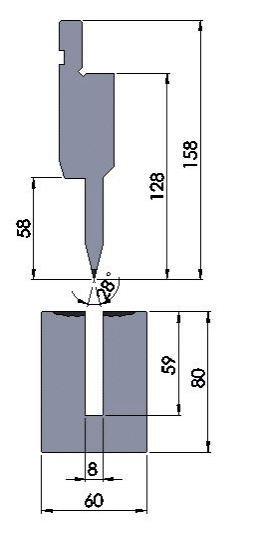

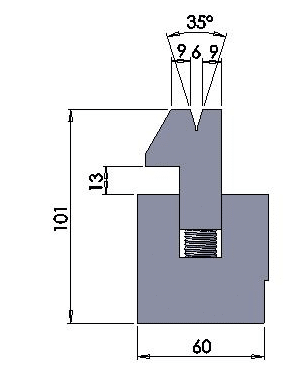

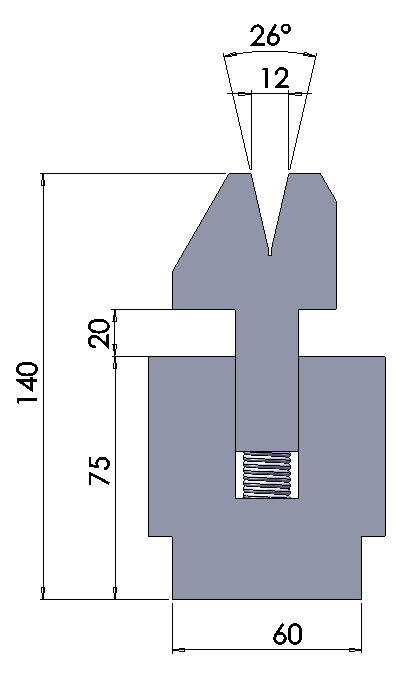

10.204

Max Tons: 40t/m

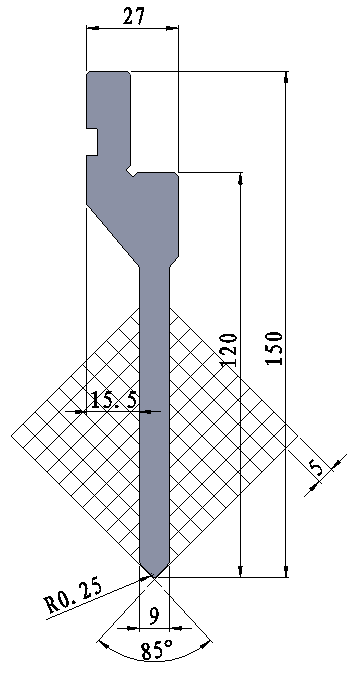

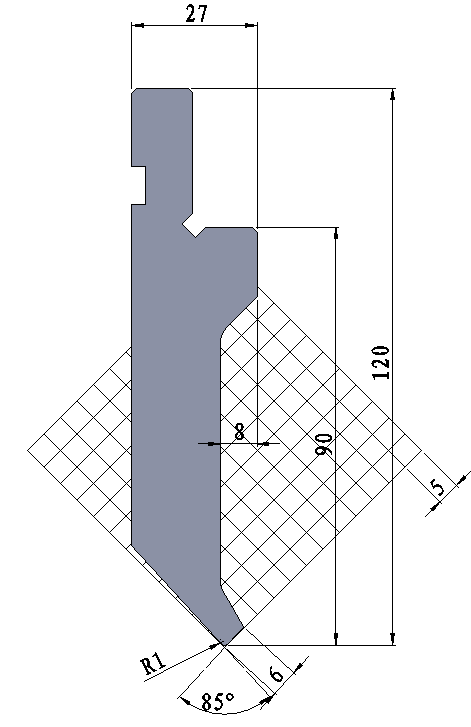

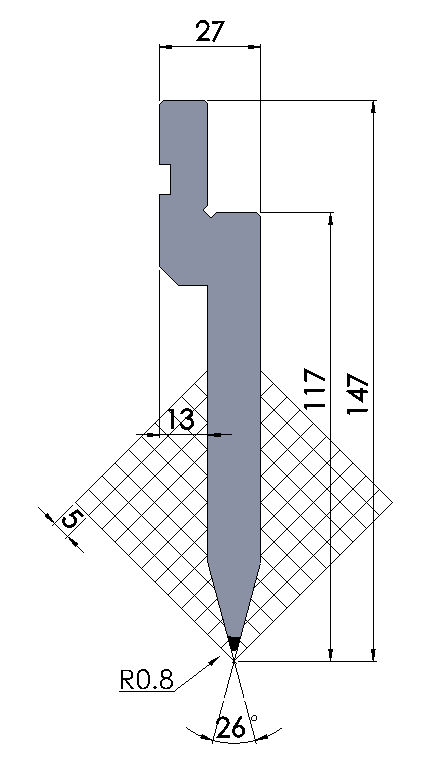

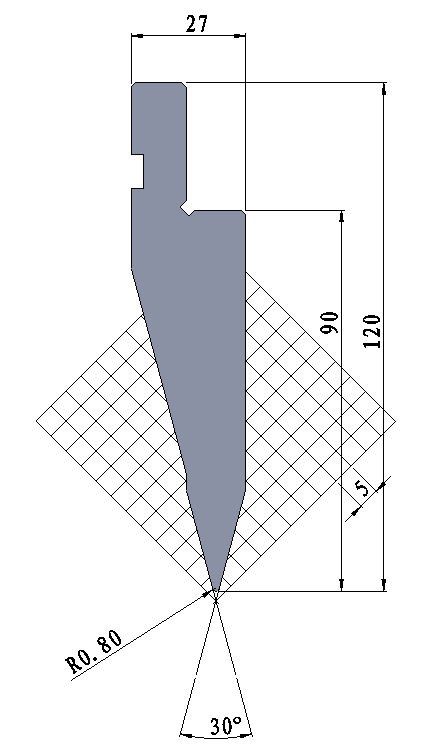

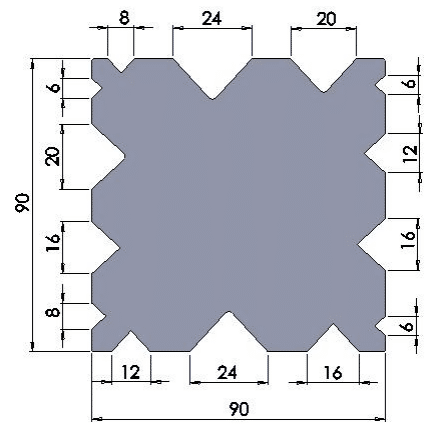

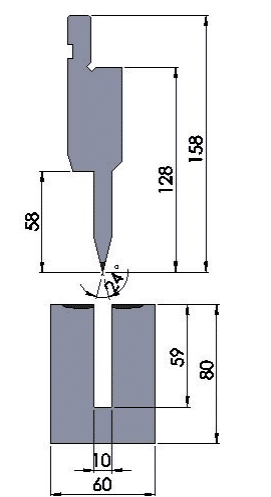

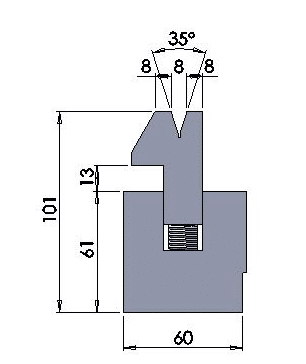

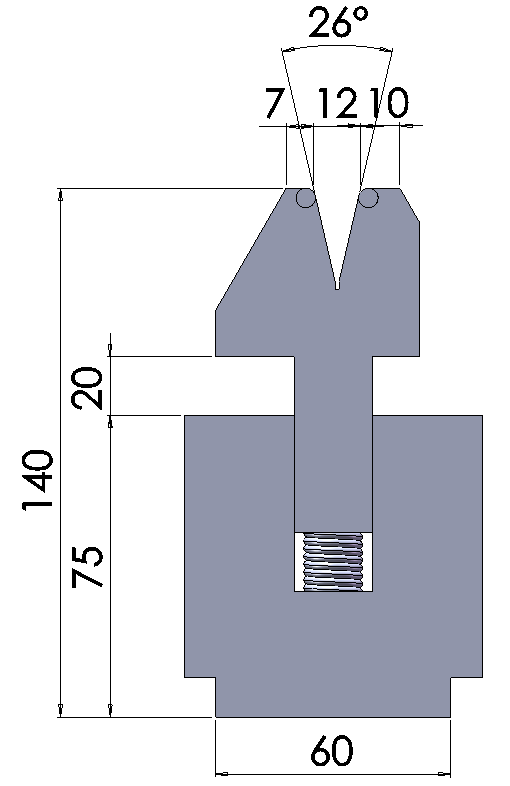

10.109

Max Tons: 70t/m

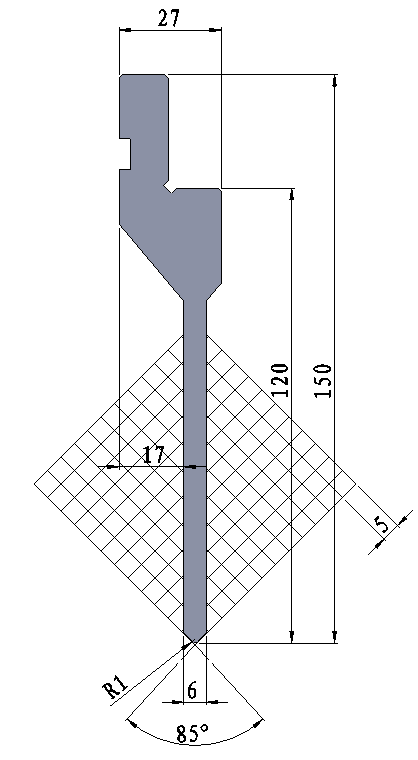

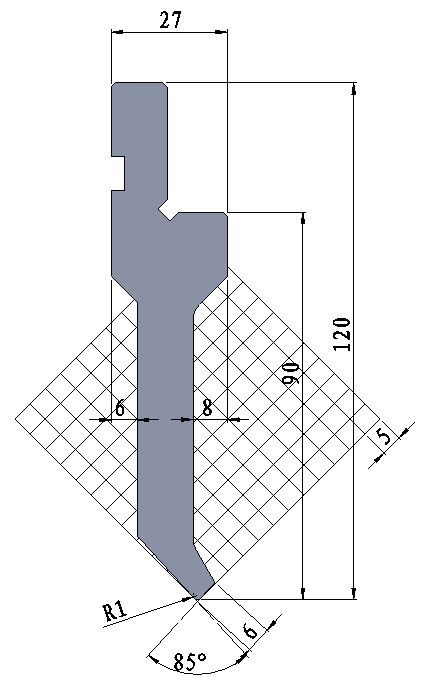

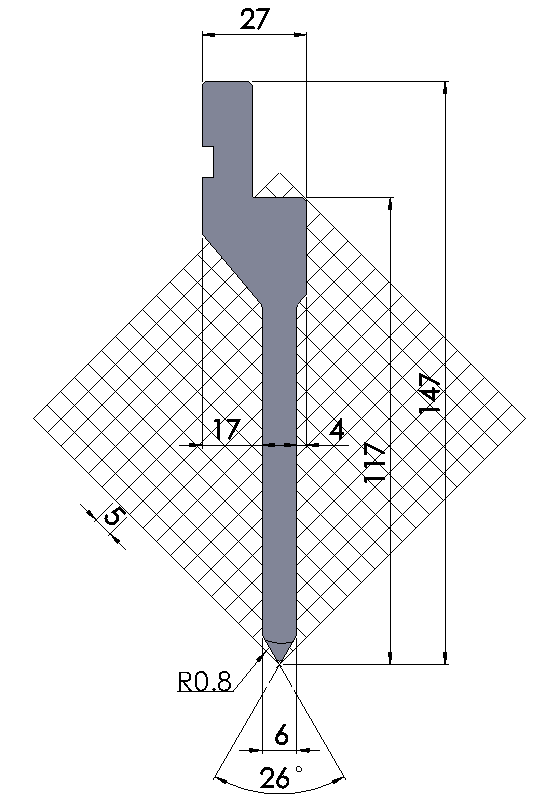

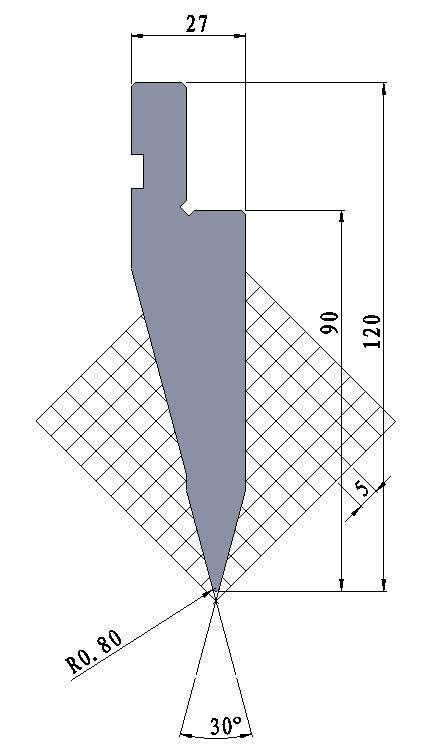

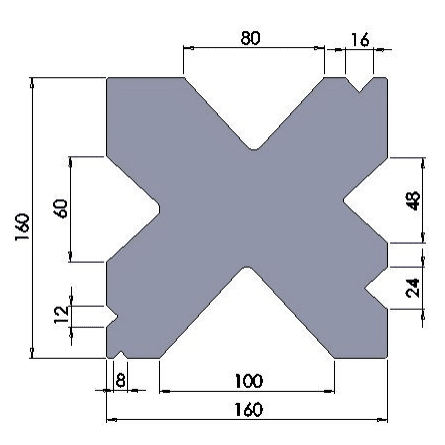

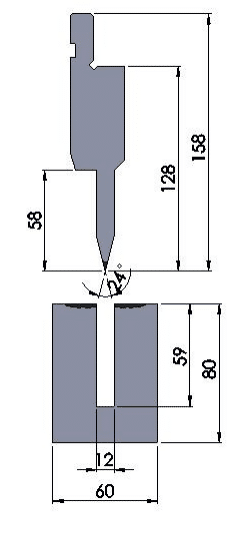

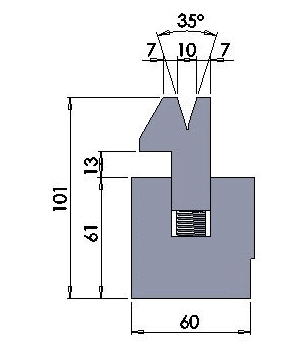

10.108

Max Tons: 50t/m

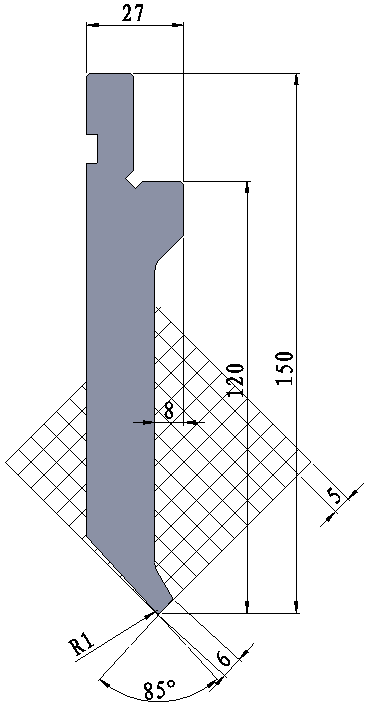

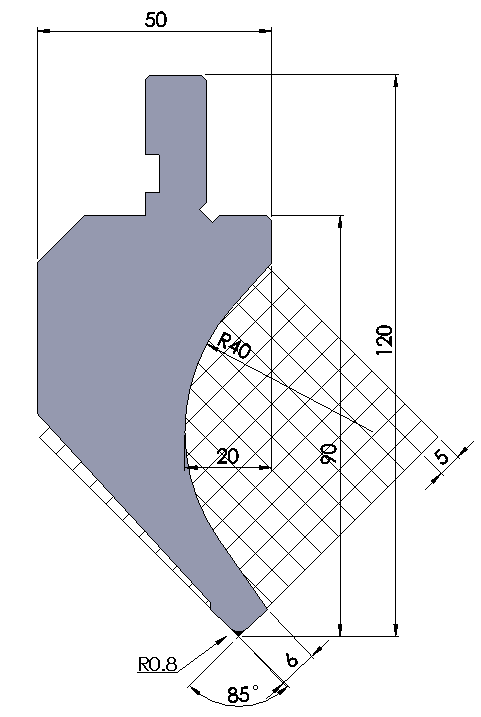

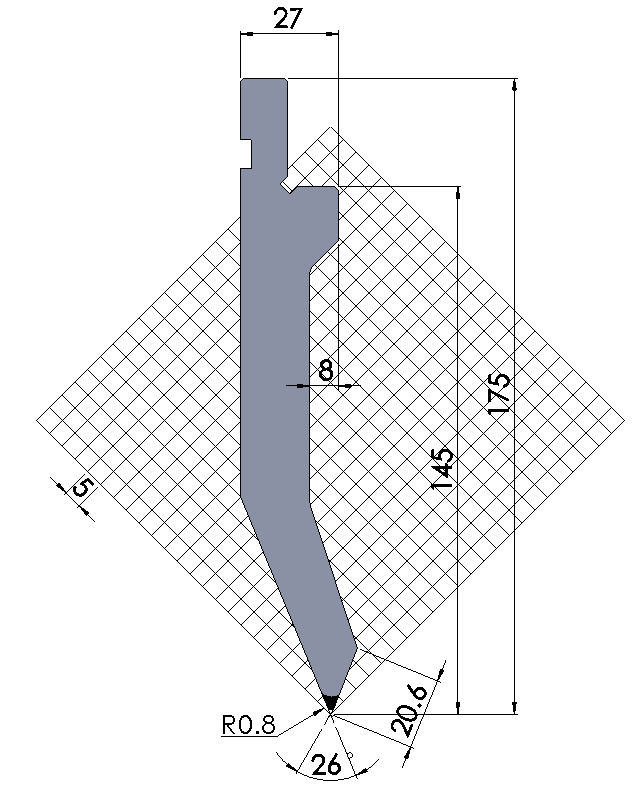

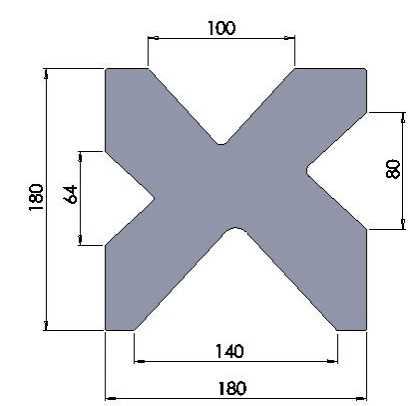

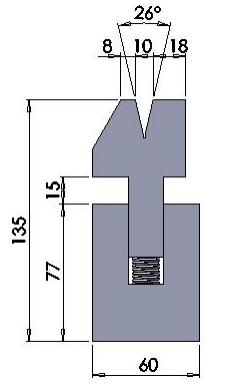

10.205

Max Tons: 80t/m

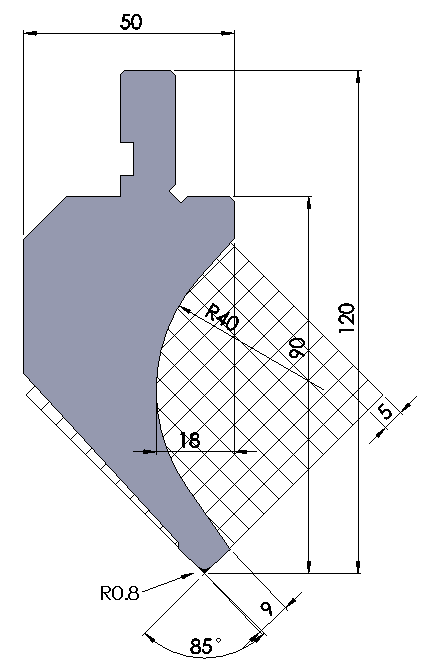

10.203

Max Tons: 100t/m

10.202

Max Tons: 90t/m

10.200

Max Tons: 80t/m

10.146

Max Tons: 50t/m

10.14

Max Tons:70t/m

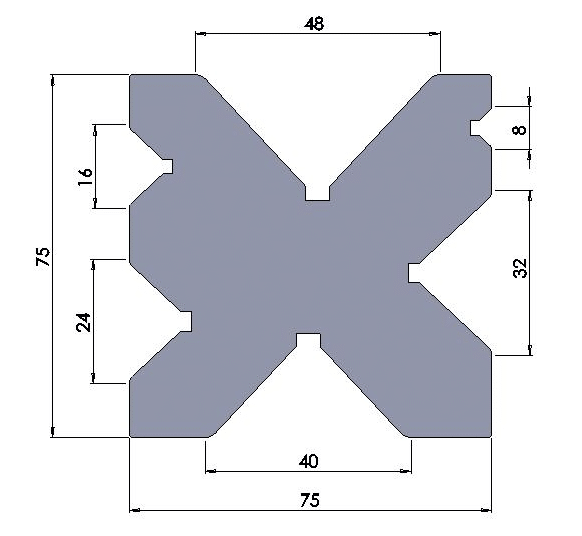

Upper Tooling Fixtures

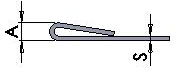

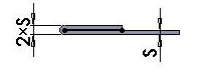

Selection Reference

| s(mm) | A (mm) | 450Mpa(t/m) | 700Mpa(t/m) | s(mm) | A (mm) | 450Mpa(t/m) | 700Mpa(t/m) | |

|---|---|---|---|---|---|---|---|---|

| 0.6 | 3.0 | 9 | 15 | 0.6 | 1.2 | 23 | 35 |

| 0.8 | 3.0 | 12 | 20 | 0.8 | 1.6 | 32 | 50 | |

| 1.0 | 3.5 | 15 | 25 | 1.0 | 2.0 | 40 | 60 | |

| 1.25 | 3.5 | 17 | 26 | 1.25 | 2.5 | 50 | 80 |

| 1.5 | 4.6 | 22 | 38 | 1.5 | 3.0 | 63 | 95 | |

| 2.0 | 5.5 | 30 | 50 | 2.0 | 4.0 | 80 | 130 | |

| 2.5 | 6.5 | 55 | 2.5 | 5.0 | 90 | |||

| 3.0 | 8.0 | 70 | 3.0 | 6.0 | 100 |