How to Calculate the Tonnage of a Hydraulic Press Brake?

Tonnage refers to the bending pressure during the bending process. The available models typically range from 30T to 2200T.How should you choose the appropriate press brake based on the daily bending workpiece requirements? The selection of the press brake tonnage is related to the length, thickness of the sheet, and the width of the lower die opening.

There are two methods for calculating the tonnage of a press brake: one is to refer to the press brake tonnage chart, and the other is to use a press brake tonnage formula.

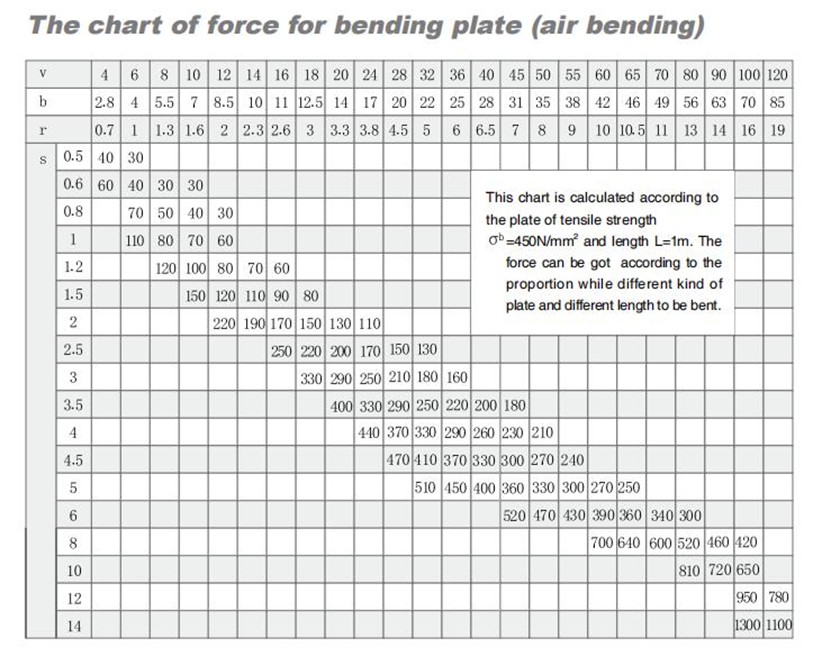

Calculate Based on The Press Brake Tonnage Chart

This chart is calculated based on the tensile strength and a sheet length of L = 1m. When bending different sheet materials and lengths, the force can be obtained based on the proportion. When bending other materials, the bending pressure is the product of the data in the table and the following coefficients:

-

- Bronze (soft): 0.5;

- 304Stainless steel: 1.5;

- Aluminum (soft): 0.5;

- Chrome-molybdenum steel: 2

Example: If the sheet thickness is S = 3mm and the length is L = 3m, how many tons are needed?

First, we refer to the press brake tonnage chart. When S = 3mm and L = 1m, V = 24mm, the chart shows P = 250KN.

So, if L = 3m, the total tonnage will be 250KN x 3m = 750KN = 75Ton.

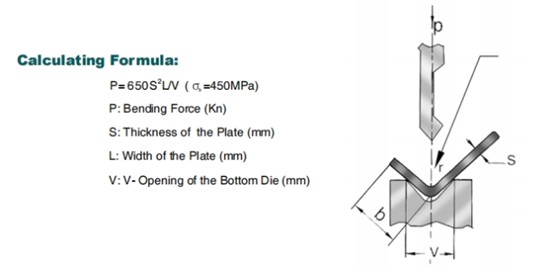

Calculate with Press Brake Tonnage Formular

The force required to bend metal sheets is calculated using the V-bending method, which involves pressing the sheet into a V-shaped die with a V-shaped punch. The bending force can be calculated based on the sheet thickness, die opening, bending length, and the material’s ultimate tensile strength.

You can input the die ratio to calculate the die opening, with the following standards as a reference:

- v = 6S, S: 0.5-2.6mm

- v = 8S, S: 3.0-8.0mm

- v = 10S, S: 9.0-10.0mm

- v = 12S, S: above 12mm

When S=3mm,L=3m

P=650 x32 x3/24≈730 KN=73Ton

The result is similar to the value we obtained from the chart.

If the sheet is made of stainless steel, we also need to multiply by the material coefficient of stainless steel, which is 1.5. The total tonnage would be 75Ton x 1.5 = 112Ton.

Assuming the thickest material is 1/4 inch, a 10-foot free bending requires 165 tons, while bending with a bottom die (corrective bending) requires at least 600 tons. If most parts are 5 feet or shorter, the tonnage is almost halved, greatly reducing procurement costs. The length of the parts is very important for determining the specifications of the new press brake.

Choosing a press brake with either too large or too small a tonnage can lead to significant risks.

Sometimes users believe that by purchasing a high-tonnage press brake, they can bend all small workpieces that meet the tonnage requirements. This is incorrect. The bending tooling designed for large press brakes is not suitable for bending small workpieces. Large press brakes usually use multi-V die bottoms, and the V-shaped gaps are too large for thin sheets. Even if the user replaces the small die with a thin sheet, the large-tonnage press brake has a wider worktable, which can sometimes affect the bending effect. Moreover, using a higher-tonnage press brake means more power consumption. If users always use a high-tonnage press brake to bend small workpieces, it wastes unnecessary energy.

If the tonnage is too small, it cannot provide enough pressure for effective bending, which may result in insufficient bending angles, uneven edges, or the need for multiple bends to achieve the desired result, thereby affecting production efficiency.