A good press brake manufacturer typically follows stricter production processes, which require more labor and time costs compared to lower-standard processes. Substandard manufacturing practices may save labor and time costs, but they can severely impact product performance. For instance, the frame formation of a press brake involves a considerable amount of welding, and the design of the main structure and its connection methods significantly affect the performance of the machine. Some manufacturers, in an attempt to cut costs, use recycled steel plates for splicing the slider and main frame, which are unable to withstand the high-strength bending forces. Moreover, in order to save on labor costs or reduce delivery times, some skip the “grooving” step during the frame welding process, which severely compromises the overall rigidity and strength of the machine. However, for an excellent press brake manufacturer, every process must be carried out according to strict standards.

High-Performance Press Brake Manufacturer — How to Make a Strength Frame

Table of Content

“Grooving” refers to the process of creating a groove with a specific geometric shape at the weld joint of a workpiece using methods such as mechanical, flame, or plasma cutting, depending on design or process requirements.

To put it simply, it’s like carving out a mortise before joining two pieces of wood together. The purpose of grooving is to provide “space” for welding.

For workpieces that exceed certain thicknesses (typically, manual welding for thicknesses over 6mm, and automatic welding for thicknesses over 10mm), grooving must be performed according to process requirements. Skipping this step is a serious violation of welding standards and can lead to significant quality risks, so it should never be omitted for the sake of convenience.

2.What An Unqualified Press Brake Manufacturer Might do?

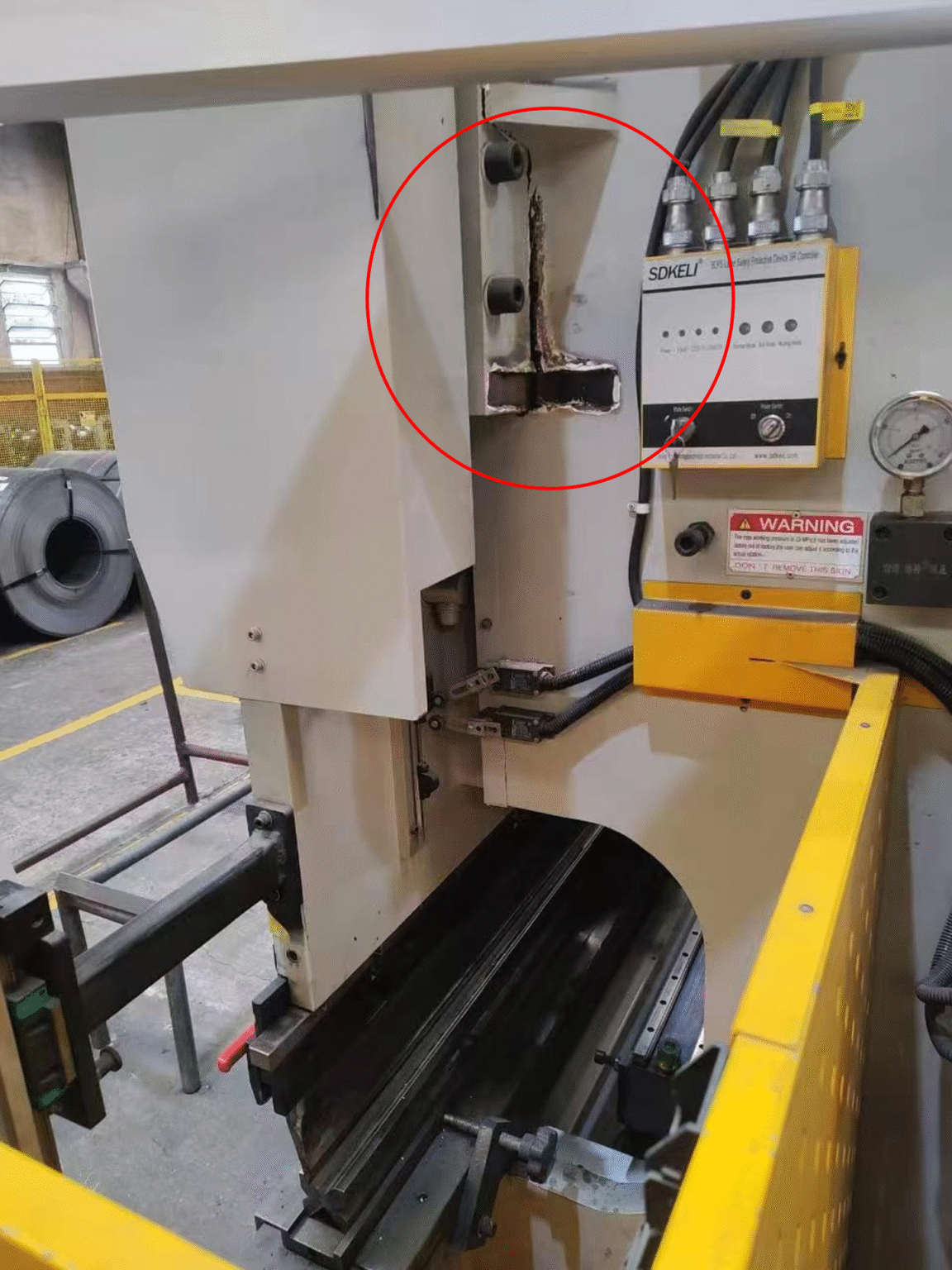

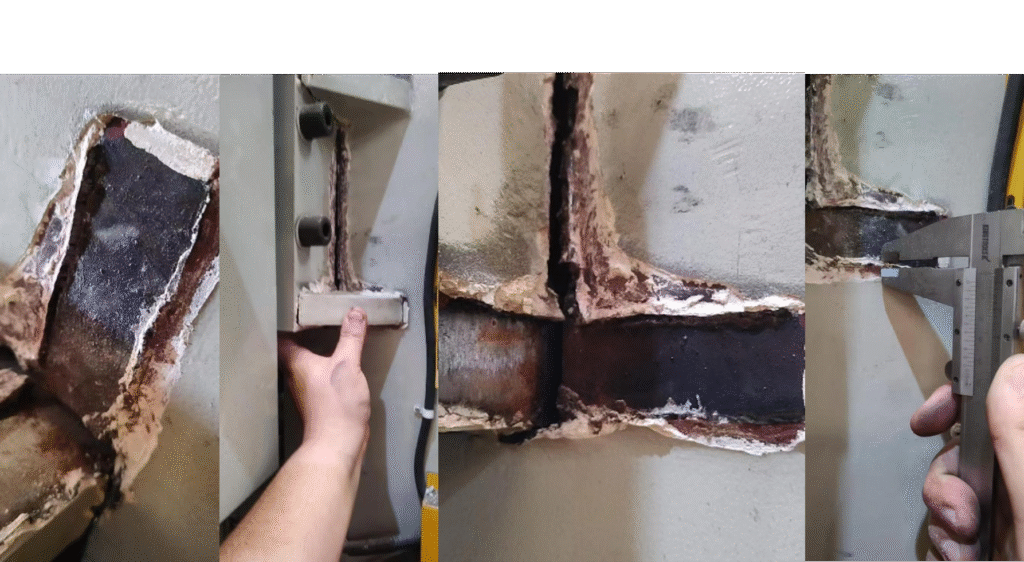

In the production process of press brakes, substandard manufacturing practices may save labor and time costs, but they can severely impact product performance. For instance, the frame formation of a involves a considerable amount of welding, and the design of the main structure and its connection methods significantly affect the performance of the machine. Some manufacturers, in an attempt to cut costs, use recycled steel plates for splicing the slider and main frame, which are unable to withstand the high-strength bending forces. Moreover, in order to save on labor costs or reduce delivery times, some skip the “grooving” step during the frame welding process, which severely compromises the overall rigidity and strength of the machine.

Here are some quality issues arising from the lack of this process in press brake manufacturing.

Here are some quality issues arising from the lack of this process in press brake manufacturer operations.

3.Why Is Grooving Necessary?

Grooving is a critical step to ensure welding quality, and its main purposes include:

• Ensuring Weld Penetration: This is the primary objective. For thicker workpieces (typically over 6mm), without grooving, it is difficult for the arc to penetrate the root of the joint, leading to incomplete fusion and significant welding defects. The groove provides a channel for the welding rod or wire to reach the deeper part of the joint.

• Reducing Welding Difficulty: Grooving transforms a thick plate into a “slope,” which makes it easier to apply welding in layers, ensuring good fusion quality for each layer.

• Controlling Fusion Ratio: By adjusting the shape and angle of the groove, the ratio of base metal to filler metal in the weld can be controlled, optimizing the weld’s chemical composition and mechanical properties.

• Reducing Welding Stress and Deformation: Compared to deep penetration welding without grooving, multi-pass welding with grooves can effectively distribute and reduce welding thermal stresses and deformations.

• Eliminating Root Defects: After welding the groove root, sometimes root cleaning operations can be performed from the backside to remove defects like pores or slag that may have formed in the first layer of welding before filling the groove.

4.Consequences of Not Performing Grooving

As a precision machine that is subjected to substantial loads, the frame welding process of a press brake manufacturer can have severe consequences if the main structure is not grooved according to standards, directly compromising the safety, accuracy, and service life of the machine.

4.1. Insufficient Structural Strength Leading to Crack Risk

This is the most critical risk.

• Incomplete Welds Leading to Stress Concentration: The frame of the press brake manufacturer undergoes significant tensile and compressive forces during operation. If the root of the weld is not fully penetrated, this gap becomes a natural “crack initiation point.” Under cyclic loading, cracks will propagate from here.

• Consequences: Under full load or overload conditions, the weld may suddenly tear, causing the entire frame to fail and potentially leading to safety accidents.

4.2. Reduced Fatigue Life

The press brake manufacturer operates in a continuous, repetitive manner.

• Micro-movement Fatigue: Unpenetrated gaps, under alternating stresses, will repeatedly open and close, causing micro-movement wear and accelerating the fatigue failure process.

• Consequences: A frame that should last for ten years may develop fatigue cracks at critical welds within one or two years, leading to premature failure of the equipment.

4.3. Loss of Rigidity and Accuracy

The press brake manufacturer’s processing accuracy (e.g., angle consistency, straightness) is highly dependent on the frame’s rigidity.

• Insufficient Effective Weld Thickness: Skipping the grooving step results in a weld throat thickness that is far below the design value. Under heavy operational loads, this weak point will undergo small elastic or plastic deformations.

• Consequences: This results in “blade slippage” — when bending thicker plates, the angles become unstable, and the preset accuracy cannot be achieved. The entire frame becomes “soft,” making it impossible to maintain product quality.

4.4. Large Residual Welding Stresses Leading to Deformation and Time-dependent Changes

• High Heat Input and Stress: To achieve penetration in thick plates, a large welding current must be used, generating excessive heat and high residual welding stresses in the weld zone.

• Post-Processing Deformation: After welding, the frame undergoes stress-relieving annealing, followed by precision machining on critical surfaces like slider mounts, cylinders, and guide rails. If residual stresses are not fully eliminated, they will re-balance during precision machining, leading to slow deformation of the frame.

• Consequences: The installed precision parts, such as sliders and guide rails, will be misaligned, causing high noise, rapid wear, loss of accuracy, and difficulty in adjustments during operation.

5. How a Qualified Press Brake Manufacturer Operates

Meca press brake manufacturer use an integrated steel plate welded structure instead of spliced welding. For the main frame and sliders (main plate & side plates), a “plug-welding” hybrid process is employed. The precision plug connection structure between the side plates and the middle plate provides a foundation strength that far exceeds traditional grooved welding. On top of this, secondary reinforcement through grooved welding enhances the structure, achieving a 1+1>2 reinforcement effect, ensuring ultimate frame stability and durability.