Retos técnicos de las plegadoras tándem

las capacidades básicas que debe tener el fabricante para fabricar una plegadora tándem Plegadora tándem | Guía técnica para el…

Cómo los fabricantes de plegadoras seleccionan bombas hidráulicas para garantizar la fiabilidad y la precisión

Lo que los fabricantes de plegadoras realmente tienen en cuenta al seleccionar bombas hidráulicas Para un fabricante de plegadoras profesional,…

Grosor de la placa del bastidor: la columna vertebral estructural que determina la precisión y la vida útil de la plegadora

Por qué los fabricantes de plegadoras priorizan el grosor de la placa del bastidor sobre la estética Desde la perspectiva…

Guía del fabricante de plegadoras: Normas de ruido, límites y métodos de ensayo (dB(A))

Guía del fabricante de plegadoras: Normas de ruido, límites y métodos de ensayo (dB(A)) Para cualquier fabricante de plegadoras, el…

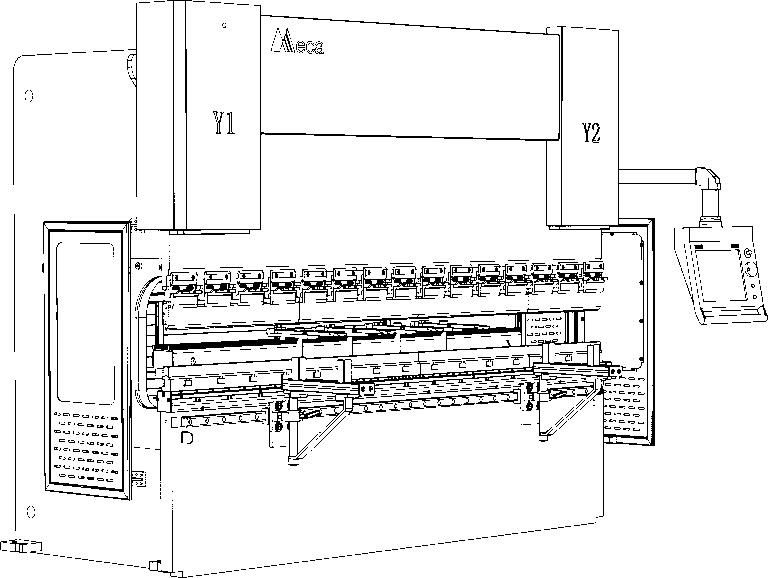

Fabricante líder de plegadoras

Fabricante líder de plegadoras

A través de procesos de fabricación de alto nivel y un estricto control de calidad, el equipo de Meca supervisa de cerca el flujo de producción de nuestras plegadoras para ofrecer máquinas de alto rendimiento que resisten el paso del tiempo.

Fábrica ubicada en: Hanjiang, Yangzhou, China

Productos principales: Plegadoras CNC, Plegadora Hidráulica, Servoplegadora, Plegadora grande, Plegadora en tándem, Plegadora personalizada, Plegadora, Plegadora eléctrica

Servicios principales:

Fabricación de plegadoras; OEM de plegadoras; Personalización de plegadoras;

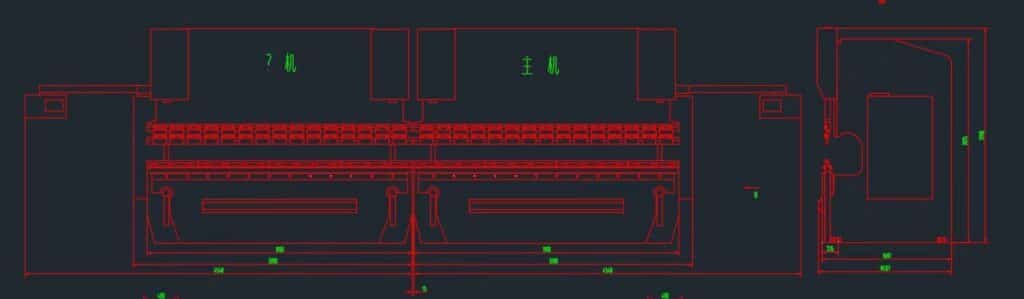

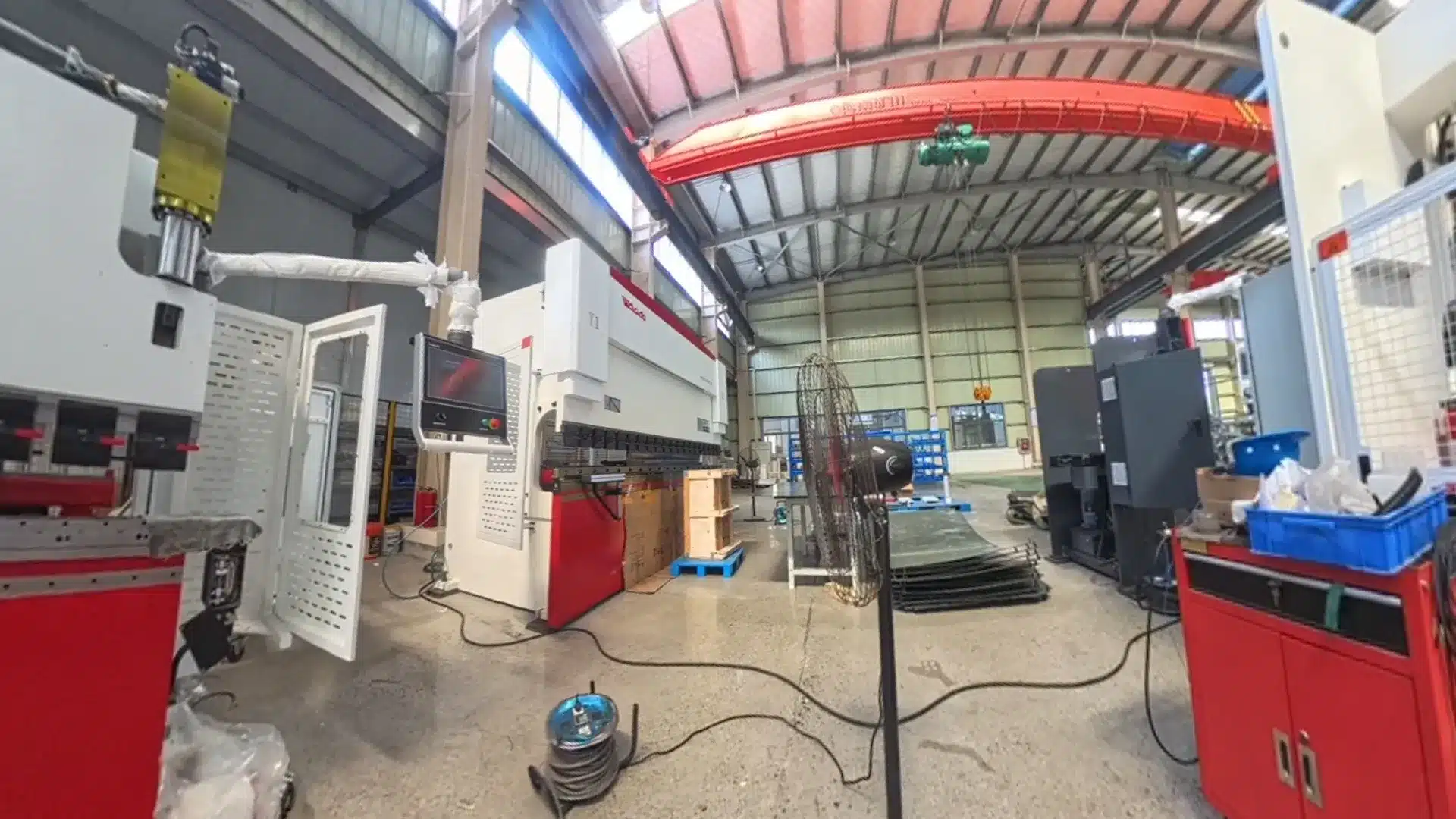

Línea de producción de prensas plegadoras CNC

En el taller se realizan tareas de corte, rectificado, soldadura y arenado del acero en bruto para las máquinas plegadoras. Está equipado con una máquina de corte por láser y una máquina de corte por oxicombustión, capaces de cortar placas de hasta 240 mm de espesor. Esto permite gestionar los procesos de corte y soldadura de materiales para prensas plegadoras de hasta 2000 toneladas y 12 000 metros. La grúa puente del taller tiene una capacidad de elevación de hasta 125 toneladas.

Se completan varios procesos de mecanizado para los componentes de la prensa plegadora, entre ellos:

* Bastidores y correderas de prensas plegadoras de 50 a 2000 toneladas

* Asientos de guía del tope trasero, dedos de tope, vigas y otras piezas de precisión

La máquina de pulverización está equipada con un sistema de adsorción de carbón activado, que captura los componentes orgánicos nocivos, mientras que el aire limpio restante se ventila. Este proceso no solo cumple las normas de seguridad y medio ambiente, sino que también garantiza un entorno de pulverización limpio, lo que se traduce en un acabado uniforme, duradero y de larga duración para la prensa plegadora.

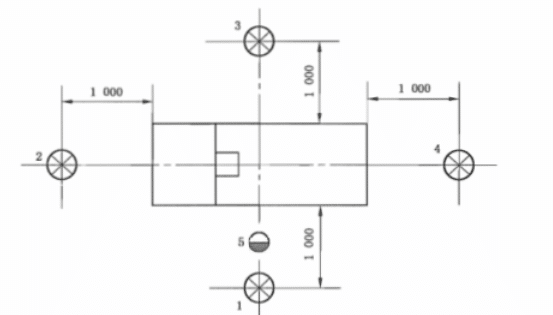

En este taller se completa todo el proceso de montaje de la prensa plegadora, incluida la instalación del motor de la bomba de aceite, el carro, los ejes X, Y y R, la escala magnética, el sistema de compensación de flexión, el armario eléctrico y las placas de circuito. A lo largo del proceso de montaje, se realizan ajustes continuos para garantizar que la precisión, los parámetros de movimiento y otras especificaciones cumplan los requisitos de entrega.

Desde acero en bruto hasta plegadoras terminadas

Gestionamos todo el ciclo de producción, desde el acero en bruto hasta las plegadoras terminadas.

Fabricante de prensas plegadoras grandes

Cómo nace una plegadora

Personalice su plegadora